Hotspots are localized regions on a photovoltaic (PV) module that exhibit significantly higher temperatures than the surrounding areas. These temperature anomalies are often invisible to the naked eye but can have serious implications for the module’s electrical performance, reliability, and safety. Hotspots are widely regarded as one of the most persistent and detrimental forms of performance degradation in solar panels, often arising from shading, cell mismatch, etc.

While the average surface temperature of a module under standard operating conditions might range between 45–70°C, hotspot regions can exceed 100°C, potentially damaging cell interconnections, encapsulants, or even causing module burnout in extreme cases. These thermal imbalances not only reduce the power output but can also shorten the lifespan of a PV system.

Causes of Hotspot Formation

Hotspots typically originate from partial obstructions or inconsistencies within a module that force certain cells or cell regions to operate in reverse bias, thereby dissipating power as heat instead of generating electricity.

- Shading Effects: One of the most common causes is partial shading due to nearby objects like trees, poles, or dirt accumulation. When a cell in a series string is shaded, it acts as a resistive load, heating up while the rest of the string continues to drive current through it.

- Cell Mismatch: Variations in electrical properties among cells, degradation, or microcracks—can result in uneven current flow. Cells with lower current generation capacity become bottlenecks, and under forced current, dissipate excess energy as heat.

- Defective Bypass Diodes: Bypass diodes are intended to protect shaded or underperforming cells by redirecting current flow. A failed or incorrectly functioning diode can leave a cell vulnerable to reverse bias operation, intensifying local heating.

- Manufacturing Defects: Localized impurities, edge isolation failures, poor soldering, and broken interconnect ribbons can introduce electrical discontinuities or elevated series resistance—both of which are conducive to hotspot development.

Impact on Performance and Safety

- Electrical Degradation: A hotspot leads to increased series resistance and non-uniform current generation, lowering the fill factor and overall module efficiency. Even a small hotspot, if sustained over time, can reduce energy yield by several percentage points annually.

- Material Damage: The localized high temperature can thermally degrade the encapsulant (typically EVA or POE), causing browning, delamination, or bubble formation. The backsheet may discolor or crack, and solder joints might melt or fail.

- Long-Term Reliability: Frequent hotspot occurrences accelerate potential-induced degradation (PID), increase the rate of interconnect fatigue, and promote the onset of arc faults. These degrade system reliability and may lead to complete module failure before the expected 25–30 year lifespan.

- Fire Hazard: In worst-case scenarios, hotspots can reach ignition temperatures for certain polymeric components. This has led to several reported incidents where hotspots contributed to electrical fires, particularly in rooftop systems with poor ventilation or insufficient monitoring.

Detection Techniques

Early detection of hotspots is essential for minimizing their impact. Several diagnostic methods are used across the industry:

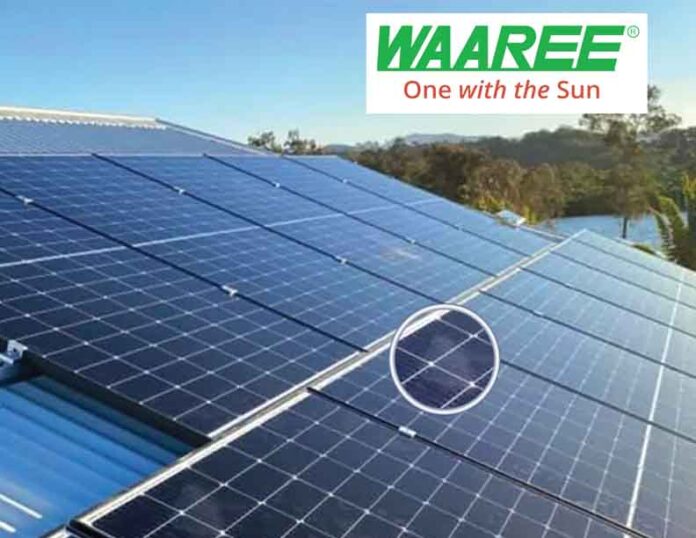

- Infrared (IR) Thermography: This is the most common field method. Using thermal cameras, technicians can visualize temperature anomalies across the module surface. IR inspection is fast and effective, especially when used under load conditions during sunny weather.

- Electroluminescence (EL) Imaging: This technique captures defects at the cell level by applying a voltage across the module in dark conditions and imaging the emitted light. Damaged or inactive cells (such as those involved in hotspots) appear dark or with diminished brightness.

- IV Curve Tracing: Deviations in the I-V curve—such as a reduced fill factor or kinks—can indicate resistive losses or damaged cells typical of hotspot-related stress.

- Drone-Based Inspection: For utility-scale plants, aerial thermographic inspections using drones can quickly identify affected modules across large areas, allowing faster maintenance responses.

Mitigation and Prevention Strategies

- Bypass Diode Optimization: Ensuring that bypass diodes are correctly designed and tested for each module type reduces the risk of reverse biasing during shading or mismatch.

- String Design and Orientation: Designing strings to minimize mismatch and avoid shading paths (like from nearby walls, HVAC units, or mounting structures) helps reduce hotspot risk.

- Regular Cleaning and Maintenance: Soiling from bird droppings, dust, or organic matter can cause hotspots. A well-defined cleaning schedule based on environmental conditions ensures consistent module performance.

- Quality Control in Manufacturing: Advanced electroluminescence screening, edge isolation, and uniform soldering techniques during production can prevent manufacturing-related hotspots.

Industry Standards and Testing

IEC 61215 includes stress tests for modules to evaluate their susceptibility to hotspots, including:

- Hotspot Endurance Test: Modules are subjected to artificially induced reverse bias conditions, and the surface temperature rise is monitored.

- Thermal Cycling and Damp Heat Tests: These accelerate aging effects to test encapsulant degradation which can be aggravated by hotspots.

In a nutshell, hotspots are a silent yet potent threat to PV module performance, often causing irreversible damage before being visibly noticeable. With the rising scale and complexity of solar installations, detecting, understanding, and mitigating hotspots is becoming more critical than ever. Through a combination of design best practices, advanced diagnostics, and robust manufacturing quality control, the solar industry can significantly curb the impact of this hidden adversary and ensure long-term system efficiency, safety, and reliability.

Submitted: R&D Dept. WAAREE Energies Ltd.