Controlled Environment Agriculture (CEA) refers to the cultivation of crops, preferably the high-value ones, inside enclosed spaces that are environmentally controlled to suit various plant growth stage requirements. Techniques such as greenhouse horticulture, vertical farming, hydroponics, and aeroponics are central to CEA. These systems enable fine control over factors like temperature, humidity, CO₂ concentration, light spectrum and intensity, airflow, as well as nutrient and water usage efficiency.

Although the producers of these CEAs can be costlier than conventionally grown crops, they are gaining rapid market acceptance worldwide, particularly among the younger population. This shift is largely driven by consumer demand for healthy, nutrient-rich, pesticide-free locally grown and traceable produce from trustworthy sources. Increased affordability, urbanisation, climate change, unpredictable weather patterns, resource constraints (especially water and nutrients), and growing concerns about food security are additional factors that accelerates the adoption of CEA technologies.

Opportunities for India

India, with its present population of 1.3 billion and projected to reach 1.6 billion in the coming years is the second largest food producer globally, after China. As the country moves towards becoming the world’s next major economic power, it faces complex challenges such as rapid urbanisation, climate change, and a growing young population. These factors, combined with the increasing demand for safe, nutritious, pesticide-free, and high-quality fruits and vegetables year-round, present a significant opportunity for innovation in agriculture.

CEA and smart farming technologies offer a promising solution to locally produced fresh agro-products using fewer resources, reduced waste, and with improved shelf life that would benefit both consumers and the broader economy. Achieving this potential requires collaboration among stakeholders, including active knowledge sharing, professional networking, and the exchange of expertise within the sector.

Trade missions and organisations from several developed countries are already supporting Indian agro-entrepreneurs by transforming innovative ideas into viable, high-yield business models. These efforts include the development of efficient greenhouse horticulture systems with guaranteed market access across India’s retail, food service, and export sectors, making high-quality, sustainable agriculture a reality.

Addressing the challenges

Having understood the solutions to the pressing challenges in agriculture, it is now ideal to explore the implementation strategy and key requirements for establishing a CEA system, particularly for greenhouses and vertical farms. This section aims to provide a micro-level overview of the critical components involved in building such systems. While not exhaustive, the focus is on identifying and introducing the main subsystems and technologies essential for successful implementation. The intention is to offer a foundation for deeper exploration, encouraging interested readers to pursue further technical understanding and best practices in the field. Various other technologies that should be implemented in CEA are explained below.

Need for grow lights

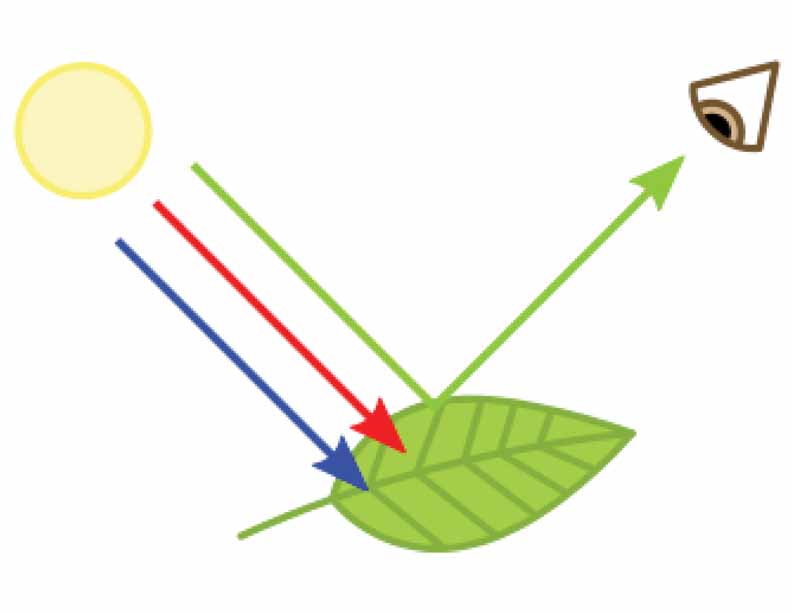

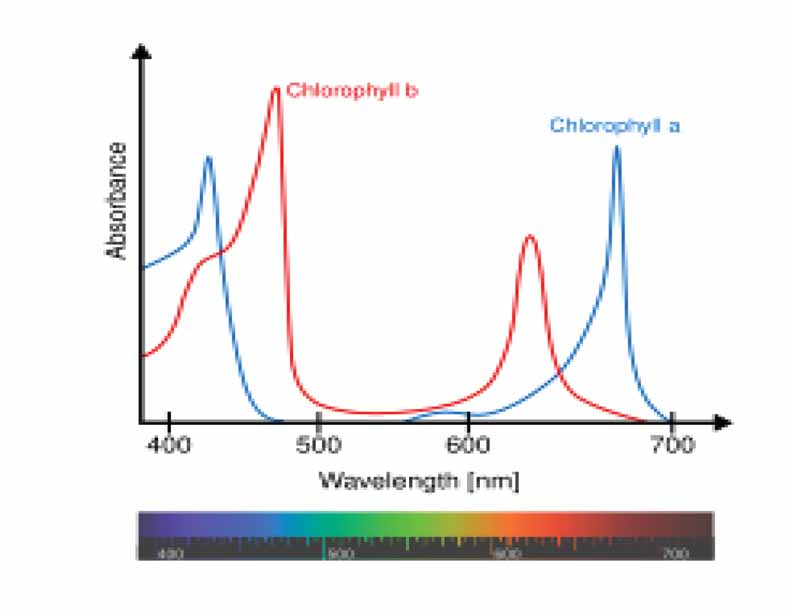

CEA, requires artificial lighting, commonly known as grow lights, plays a critical role in supplementing or replacing sunlight. These lights are designed to emit specific wavelengths of light that match the absorption spectrum of chlorophyll and other plant pigments. By precisely controlling the light intensity, spectral composition, and photoperiod (timing and duration), growers can significantly enhance photosynthetic efficiency, accelerate plant growth, improve biomass production, and ultimately achieve higher yields and better crop quality.

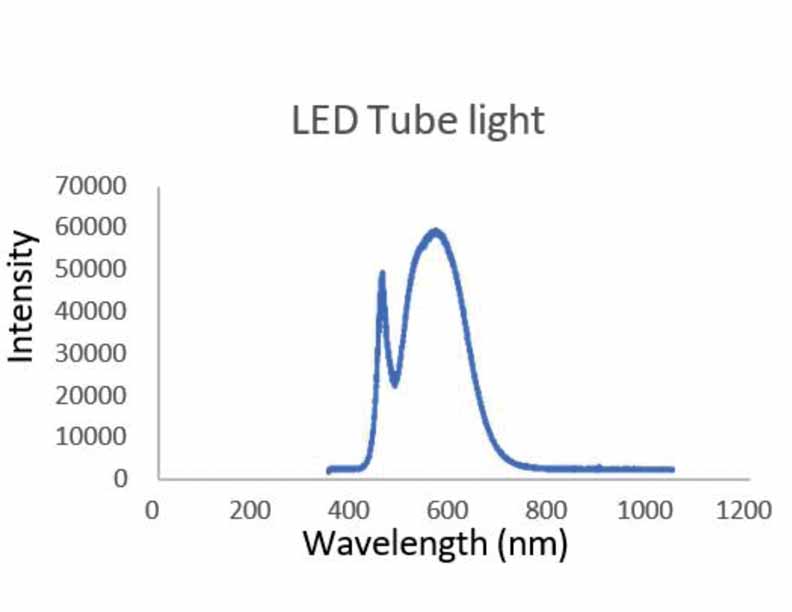

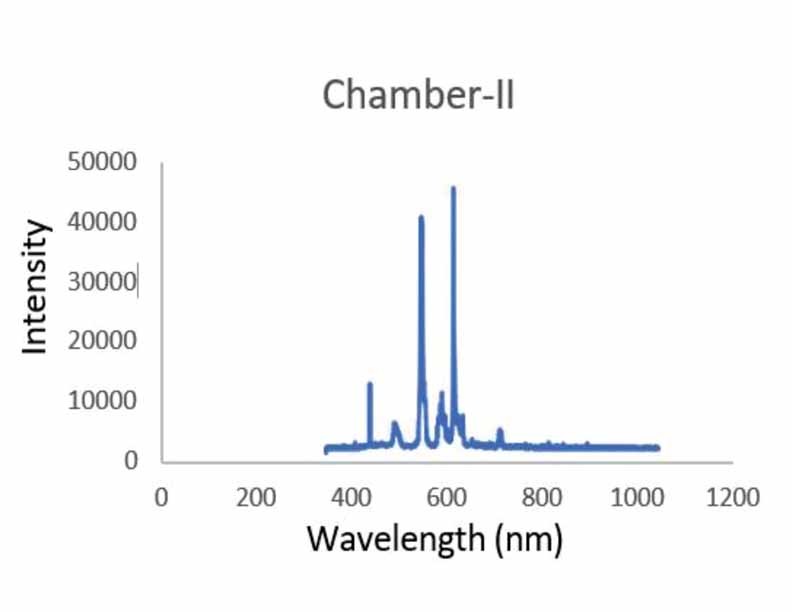

Advanced LED grow lights are now widely used due to their energy efficiency and tuneable spectra, allowing for fine-tuned lighting strategies tailored to different crop types and growth stages. Figures 1 to 4 compares the light spectrum emitted by a typical commercial LED tube with that of the optimal spectral requirements for plant growth under grow light conditions.

As an example, ‘grow light setup’ requirement for Microgreens cultivation in CEA setup (that would ensure adequate photosynthetic activity) typically involves providing a light spectrum rich in blue (≈450 nm) and red (≈660 nm) wavelengths, which are most effective for chlorophyll absorption and plant development.

A recommended Photosynthetic Photon Flux Density (PPFD) in the range of 200–400 µmol/m²/s should be maintained over the crop canopy. The grow light should be operational for 12 to 16 hours per day, simulating an optimal photoperiod for healthy growth.

Key factors such as the distance between the grow light and the plant canopy, and the angle of light incidence, directly influence the light distribution efficiency, energy consumption, and operational costs. Proper positioning and design of the lighting system are therefore critical for achieving both biological effectiveness and economic efficiency in indoor farming.

Temperature, humidity, CO₂, and air velocity management

In Controlled Environment Agriculture temperature and humidity are two of the most critical climatic variables, as they directly affect plant metabolism, photosynthesis, transpiration, flowering, fruiting, and even disease resistance. Maintaining the right balance of these parameters is vital to ensure optimal crop performance. Proper temperature control ensures efficient enzymatic activity and growth rates, while precise humidity management helps to regulate transpiration- a vital activity that transports nutrients from the roots to the aerial parts of the plant, fungal prevention or bacterial infections.

Temperature: It is a key environmental factor that regulates the rate of chemical and biological processes in plants which nearly influences every aspect of plant growth, including photosynthesis, respiration, nutrient uptake, and enzyme activity. In general, plants require higher daytime temperatures to support photosynthesis, and lower night time temperatures to facilitate respiration and energy conservation and varies between plant species. This also governs the phonological cycle of plants – the timing of key life events such as budburst, flowering, fruit development, and leaf senescence. These events are tightly linked to environmental cues, and disruptions in temperature patterns can affect crop yield, quality, and timing.

Humidity: It refers to the amount of water vapour present in the air, and it plays a crucial role in regulating a plant’s water balance and transpiration, cooling the leaf surface, and maintaining osmotic balance within plant cells. However, if humidity is too low or too high, it can disrupt transpiration, leading to water stress, nutrient deficiency, reduced photosynthetic efficiency, and ultimately a decline in growth and productivity.

Soil moisture content, which defines the amount of water the soil can retain-must also be continuously monitored and managed. Advanced sensors with automated irrigation systems are commonly used in modern CEA setups to ensure precise moisture control.

Although crop-specific temperature and humidity data are available and should be used for precision farming, a general temperature range of 15°C to 27°C and humidity range of 60–70% RH is considered suitable for most horticultural crops under controlled environment cultivation.

Air velocity: It is another important parameter to control in CEA as it affects transpiration rates, gas exchange, temperature uniformity, and overall plant health. Optimal airflow ensures proper distribution of CO₂, prevents localised humidity build-up, and reduces the risk of fungal diseases and stagnant microclimates.

The ideal air velocity varies depending on the crop type and growing setup. Sustained exposure to high wind may dry out the growing medium, causing plant stress that leads to issues such as leaf deformation or wilting. Therefore, air velocity must be carefully monitored and moderated.

CO2 Optimisation: It is a critical strategy for maximising plant growth, yield, and overall productivity in greenhouse environments. Elevated CO₂ concentrations stimulate the rate of photosynthesis, resulting in faster growth, larger fruit size, earlier harvests, and in some crops, improved resistance to diseases.

With adequate CO₂ enrichment, plants can reach maturity more quickly, improving crop turnover and efficiency. However, since CO₂ requirements vary among plant species, it is important to determine the optimal concentration through research or crop-specific guidelines. While elevated CO₂ is beneficial for plants, concentrations above 5,000 ppm can pose serious health risks to humans and hence will have to be carefully monitored and controlled. In general, CO₂ levels in the range of 800–1,200 ppm, Air velocity between 0.5 m/s to 1.5 m/s are considered beneficial for many greenhouse crops.

Readiness of Indian industries for CEA farms

CEA farms operation and achieving its optimal performance of plant health, yield, and resource efficiency requires continuous monitoring, integrated & precise control of key environmental parameters like temperature, humidity, CO₂ concentration, air velocity, and grow light intensity etc., that are tailored to the crop’s needs, in the prevailing conditions demands an effective and integrated management. It also needs HVAC, infrastructure building firms in addition.

A development in India

Presevi Industries Pvt. Ltd., a Chennai-based company with 39 years of expertise in Original Design Manufacturing (ODM) for HVAC servicing, has successfully designed and developed integrated solutions encompassing all critical environmental control functions, complete with sensor-based automation.

These specialised, networkable electronic controllers are tailored for Controlled Environment Agriculture (CEA) applications such as greenhouses, vertical farms, and other horticultural setups. Several Indian companies, both large and small – such as VOLTAS and BLUESTAR – possess proven expertise in HVAC system design and manufacturing. Additionally, the engineering capability required to develop other supporting infrastructure for CEA is well known to industry stakeholders.

Conclusion

It is high time that India, with its agro-based economic growth, focuses on Controlled Environment Agriculture (CEA), especially since it is offering solutions to current climate change and its impacts, resource constraints, give higher yields, supports the cultivation of pesticide-free agricultural produce etc.

This approach not only would help feed our growing and energetic youth population but also open opportunities to serve global markets through agricultural exports.

Achuthan Nedunghat an Electrical Engineer by profession, holding an M.S. (by Research) from the Indian Institute of Technology (IIT) Madras, Chennai, India, with a distinguished career spanning over 45 years in research, consultancy, education, engineering skill development, and entrepreneurship. He has demonstrated expertise in networkable & mechatronics-based product design for HVAC systems and washing machines, with emphasis on built-in reliability through methodologies like FTA, FMECA, MTBF, MTRR, and System Availability.