With a view to improving energy efficiency, lower operational costs and enhance occupant comfort, one of the major targets of today’s HVAC industry is to ensure how heat loss can be reduced to the best possible extent.

In this journey, by minimising heat transfer and air leakage through proper insulation and sealing, HVAC installations can maintain consistent indoor temperatures with less effort, reducing the workload on consisting equipment and extending their lifespan. This directly translates to lower energy consumption, reduced carbon emissions and a healthier indoor environment.

Why is prevention of heat loss gaining priority nowadays?

With rising global temperature, and increasing awareness of climate deterioration, the global focus is now concentrating on energy savings, as still in 2025 thermal energy is projected to account for approximately 50 to 55% of total global electricity generation. Benefits of heat loss prevention may be shortlisted as below:

- Energy savings and cost reduction: HVAC systems consume a significant portion of a building’s energy. Preventing heat loss ensures that heated or cooled air reaches its destination, preventing the system from running longer or harder to compensate, which leads to lower energy bills.

- Improved equipment performance and durability: When heat transfer is minimised, the system’s components, such as the compressor, have less work to do. This reduces wear and tear, improves performance, and extends the equipment’s lifespan.

- Enhanced indoor comfort: Preventing heat loss helps maintain consistent temperatures throughout a building, eliminating hot or cold spots and creating a more comfortable and productive indoor environment.

- Better Indoor Air Quality (IAQ): Heat loss issues are often linked to air leaks that can allow polluted outdoor air to enter the building or prevent proper ventilation. Preventing these leaks helps maintain a healthy indoor environment by ensuring the system can effectively manage air exchange.

- Reduced carbon emissions: By lowering energy consumption, preventing heat loss directly contributes to a reduction in the carbon emissions associated with energy generation, especially when that energy comes from fossil fuels (especially coal).

Right insulation can help in preventing heat loss

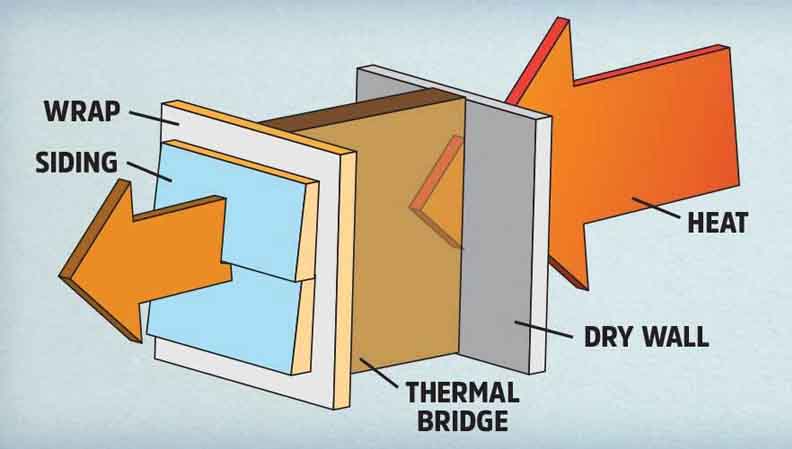

Selection of the right insulation material and its appropriate installation is very important. To prevent heat loss in HVAC, choosing proper thickness and low thermal conductivity of the insulation material – and installing that without gaps or thermal bridging is imperative. Equally important is maintaining proper cleanliness and dryness of the insulation. There are some basic steps, as enlisted below that help in preventing heat loss through insulation.

- Selection of the right material: Choosing insulation with low thermal conductivity λ (λ = lambda) values and appropriate thickness for the temperature differences the system will experience is very essential. Also, attention should be paid on moisture and fire resistance capability of the material based on the location and local environment of the installation.

- Proper installation: Ensuring that the insulation covers the entire surface without leaving any gaps is necessary. All joints and seams must be sealed with closed-cell adhesive tapes to prevent air leaks and condensation. Avoiding thermal bridging by securing pipes to supports without compressing the insulation is very important. Equally important is considering a water vapour barrier to prevent moisture from permeating the insulation, which can damage it and reduce its effectiveness.

- Maintaining the insulation: To prevent degradation of its thermal performance, regular cleaning of the insulation is essential. Also, there should be a practice of intermittent monitoring of the system performance – using tools like thermal imaging or sensors to identify areas where heat loss is occurring. It is also important to perform regular maintenance on the HVAC system components, such as seals and doors, to ensure they are not compromising the insulation’s effectiveness.

Insulation materials that are gaining popularity now

Certain essential qualities like low thermal conductivity, high moisture resistance and high durability are essential for a good insulation material. That apart fire resistance, acoustic dampening, and cost-effectiveness, are also important.

At present, being driven by regulations and a demand for energy efficiency, sustainable materials and advanced performance, several new and enhanced insulation materials are gaining popularity in the HVAC industry. The following advanced materials offer superior thermal resistance and performance, often with thinner profiles:

- Aerogels: As one of the best thermal insulators, silica aerogel offers extremely low thermal conductivity. While historically expensive, breakthroughs in production are lowering costs. Its key advantages include ultralight weight, excellent fire and moisture resistance, and the ability to achieve high R-values in confined spaces like pipework and tight wall cavities.

R-value is a measure of thermal resistance in HVAC insulation materials, indicating how well they can resist the flow of heat. A higher R-value means better insulating performance, which keeps homes cooler in the summer and warmer in the winter, leading to greater energy efficiency and lower costs. The value is determined by the material, its thickness, and its density, and R-values can be added together for multiple layers to get the total resistance.

- Nano-microporous insulation boards: Made from nano-sized silica and ceramic fibres, these rigid or flexible boards have a thermal conductivity even lower than still air. They offer performance far superior to conventional materials – and are gaining traction in HVAC for industrial, commercial, and space-constrained applications.

- Advanced foams: High-performance plastic foams are evolving with improved thermal and fire resistance. These include:

- Polyisocyanurate (PIR): A rigid foam with high thermal efficiency and non-flammable properties, ideal for commercial and industrial uses.

- Elastomeric foam: A closed-cell foam that offers flexibility, moisture resistance, and a built-in vapour barrier, making it excellent for controlling condensation in humid environments and on cold lines.

Smart and multifunctional materials

In order to address the rising demands for energy efficiency, Indoor Air Quality (IAQ), enhanced user control and predictive maintenance, the HVAC industry is moving toward integrated solutions that can provide more than just thermal resistance. A few examples thereon are listed below:

- Smart insulation systems: Embedded sensors and IoT devices in these systems can monitor real-time temperature, humidity, and energy usage. This data enables predictive maintenance and optimises HVAC performance to maximise energy savings.

- Phase Change Materials (PCMs): These materials, integrated into boards or building elements, absorb and release thermal energy during phase transitions to regulate temperature. In buildings, this helps manage internal temperatures and reduces the load on HVAC equipment.

- Acoustic insulation: With a growing focus on occupant comfort, materials that offer sound-dampening qualities in addition to thermal resistance are becoming more popular. Mineral wool and certain fiberglass products are being developed specifically for this application, particularly in commercial and institutional settings.

Sustainable, green materials for HVAC insulation

Green insulation products for HVAC include cellulose, recycled cotton/denim, sheep’s wool, aerogel and natural or plant-based foams because they are made from recycled or renewable materials. They are non-toxic, and they provide excellent thermal and acoustic performance. Other options like mineral wool and cellular glass offer high fire resistance, durability, and moisture resistance, while newer products like straw panels are effective and contribute to carbon sequestration.

Nowadays consumer demand and government regulations are driving the adoption of greener insulation products.

- Recycled and bio-based materials: Made from recycled paper (cellulose), recycled denim, or natural fibres like sheep’s wool and cork, these options have a lower environmental footprint and can contribute to green building certifications.

- Low-VOC materials: In response to a greater focus on indoor air quality, manufacturers are producing insulation with low or zero Volatile Organic Compound (VOC) emissions, especially for use in residential, healthcare and educational facilities.

- Mineral wool advancements: Manufacturers like ROCKWOOL are using stone wool to create products with enhanced thermal performance and fire resistance. These sustainable, non-combustible materials are recyclable and durable.

A few recent developments in this field

Recent developments in heat insulation materials focus on advanced aerogels, sustainable natural-fibre composites, and high-performance coatings. Aerogels are being engineered with nanoporous structures to achieve lower thermal conductivity, while natural fibres from agricultural waste are being explored for eco-friendly and cost-effective insulation. Additionally, infrared-reflective coatings and bio-inspired designs are being developed to enhance performance and create ‘smart’ insulation that responds to temperature changes. A few such examples are cited below:

Source: Image by Bingqian Li from pexels

Advanced materials

- Aerogels: Nanoporous aerogels are being refined for extremely low thermal conductivity (at room temperature) by controlling pore size and using infrared shading agents.

- Ceramic micro-nanofiber membranes and aerogels: Researchers are processing 2D ceramic fibres into 3D aerogels to improve porosity and flexibility for high-temperature applications.

- Phase Change Materials (PCMs): PCMs, such as paraffin wax, are being enhanced with materials like carbon nanotubes or silica shells to improve thermal conductivity and prevent leakage for applications like battery thermal management.

Sustainable and natural materials

- Natural fibre composites: Lignocellulosic wastes, like agricultural waste, are being used to create composites with binders to produce lightweight, renewable, and compostable insulation materials.

- Plant-based insulation: Materials are being developed from date palm fibres and pineapple leaf fibres, offering promising thermal performance and low moisture content.

- High-density fiberglass: Higher density batts are being produced for use in areas with limited space, such as cathedral ceilings, offering higher R-values for the same thickness.

High-performance and ‘smart’ materials

- Reflective coatings: Infrared-Reflective Coatings (IRCS) are being applied to surfaces to increase reflectivity, reduce heat absorption, and improve the overall thermal performance of buildings.

- Bio-inspired insulation: Research is exploring how to apply principles from biological systems to create insulation materials that can dynamically adapt to environmental conditions.

- Vacuum insulation panels: These are being developed for specialised, high-performance applications requiring exceptional insulation capabilities.

By P. K. Chatterjee (PK)