At present, the field of cold chain logistics experiences significant growth, with refrigeration playing a pivotal role in cold chain transportation. Refrigerated transportation is a vital part of modern supply chains, tasked with maintaining consistently low temperatures to ensure the quality and safety of perishable, volatile, and temperature-sensitive goods.

Conventional refrigerator used in cold chain logistics typically employs mechanical compression refrigeration, primarily driven by internal combustion engines, leading to significant energy dissipation – and relatively reduced operational efficiency of the entire refrigeration system. Moreover, the loading and unloading of goods during transportation involve frequent starts and stops of the refrigeration unit, resulting in a loss of cold capacity within the compartment and compromising the freshness of the products.

Additionally, fossil fuels remain the primary energy source for mechanically refrigerated transport vehicles. Given the escalating depletion of resources in contemporary society, the need to substitute clean energy sources cannot be disregarded.

Investing in the state-of-the-art technology, developing specialised storage facilities, and adopting sustainable practices can give a business a competitive edge – and position it for long-term success in the cold chain logistics industry. The cold chain logistics sector in India is undergoing significant transformation. The use of cutting-edge technology, the development of specialised storage facilities, and the focus on sustainability are all influencing the industry’s landscape.

By comprehending these evolving trends and adjusting to the shifting market demands, entrepreneurs can capitalise on the opportunity presented by the growing demand for cold chain solutions in India.

Cold rooms, also known as refrigerated storage rooms or walk-in freezers, are specialised enclosures designed to store goods at controlled temperatures. These rooms play a vital role in industries such as food processing, pharmaceuticals, chemicals, and agriculture. By maintaining optimal temperature and humidity levels, cold rooms help preserve the quality of products, reduce waste, and extend shelf life.

As technology continues to evolve, so too does the design and functionality of cold rooms. From advanced refrigeration systems to smart monitoring tools, cold room technology has come a long way in terms of energy efficiency, user-friendliness, and adaptability.

As industries demand greater efficiency and sustainability, the future of cold room technology looks toward innovations that address not only the technical aspects but also the environmental and economic challenges of refrigeration. Cold room solutions are integral to a variety of industries, with food storage being one of the most significant sectors relying on refrigeration technology.

With global food production and consumption constantly rising, the need for effective cold storage solutions has never been more important. A vast majority of food items, from fruits and vegetables to dairy and meat products, require proper refrigeration to maintain their quality and prevent spoilage. Cold room solutions also help reduce food waste by extending the shelf life of perishable goods.

In addition to food storage, cold rooms are also essential in the pharmaceutical industry. Vaccines, biologics, and temperature-sensitive medications must be stored in precisely controlled environments to maintain their efficacy. As the global demand for vaccines and biologics increases, the need for advanced cold room solutions that provide reliable, high-capacity storage is critical.

The logistics and transportation industry also relies heavily on cold room technology, particularly in the movement of perishable goods. Cold chain logistics ensures that products remain at the correct temperature throughout the transportation process, maintaining product quality and safety. The future of cold chain technology is being shaped by several key trends that focus on improving efficiency, sustainability, and flexibility. These trends reflect the growing demand for solutions that can adapt to changing environmental, economic, and operational conditions.

Latest Advancements in Cold Storage Technology

Automated Guided Vehicles (AGVs)

AGVs are self-guiding vehicles that can move goods throughout a warehouse without assistance from a person. These vehicles have sensors and navigation systems that enable them to move things from one place to another while navigating through the warehouse. Chilled warehouses may considerably increase the efficiency and accuracy of order fulfillment and lessen their reliance on manual labour by using AGVs.

Automated Storage/Retrieval Systems (As/Rs)

Another crucial element of automation in refrigerated warehouses is AS/RS systems. These systems are made up of automated storage and retrieval devices that can quickly store and take items out of the warehouse from certain areas. Large volumes of inventory can be managed via AS/RS systems, which also make the best use of the warehouse’s space. Chilled warehouses can reduce errors, boost efficiency, and boost throughput speed by automating the storage and retrieval procedures.

Advanced Sensors and Vision Systems

Other robotic technologies are gaining ground in refrigerated warehouses in addition to AGVs and AS/RS systems. Robots can carry out activities like picking and packing, inventory tracking, and quality control – thanks to their sophisticated sensors and visual systems. These robots can cooperate with human workers, enhancing their efforts and raising output in general.

Enhanced Visibility and Communication System

Cold chain businesses must improve communication and visibility on a worldwide scale if they want to manage shipments more efficiently. The speed of decision-making is essential for achieving this. Control Tower systems provide real-time visibility over all drivers’ shipments to meet this need, empowering organisations to act quickly and wisely.

Control Tower systems give companies a centralised platform from which to track and monitor the status of shipments throughout their entire network. Businesses can gain a thorough understanding of their operations regardless of location – thanks to this global visibility. Businesses are able to make wise decisions to increase their supply chain efficiency and overall efficiency when they have this degree of information.

Optimisation of the Cold Storage Solutions via Analytics

An analytics-based optimisation is a potent tool that helps firms find inefficiencies and learn about how to expand. By processing billions of data points produced by last-mile processes, sophisticated algorithms can expose hidden layers of inefficiency that could otherwise go undetected. These algorithms surpass the skills of regular people, giving firms simple dashboards that deliver insightful data for improvement.

Drive-through Dock for the Cold Storage Solutions

For maximising energy efficiency and maintaining the integrity of the cold chain, the drive-through dock design is regarded as the gold standard in the cold storage industry. It is the best option for contemporary cold storage facilities because of its capacity to reduce energy loss, improve traffic flow, and increase security. Businesses may cut their energy usage, preserve the quality of their products in storage, and boost overall operational effectiveness by putting this design into practice.

Use of Sustainable Materials Known as Phase Change Materials (PCMs)

PCMs are substances that, while undergoing phase transitions like melting or freezing, may absorb or release thermal energy. They are employed in cold chain packing, particularly for medicines, and they maintain the intended temperature range of the goods even while in transportation.

RFID Technology

Temperature sensors and Radio Frequency Identification (RFID) tags work together to offer two benefits. They make sure that things are always in the correct place at the proper temperature by tracking not just the product’s location but also its temperature.

Cloud-based Cold Chain Management

Cold chain management has advanced significantly with the introduction of cloud computing. Through cloud-based solutions, stakeholders may monitor storage facilities, obtain temperature data, and even remotely modify some settings.

Modern Insulation Materials

There have been major breakthroughs in the insulation used in cold chain storage and transportation. Better insulation is known to be found in materials like aerogels and vacuum-insulated panels.

Battery-backed Power Systems

For cold chain storage, power disruptions can be disastrous. Battery-backed power systems are common in modern buildings, guaranteeing that cooling will continue even in the case of a power outage.

Real-time Monitoring

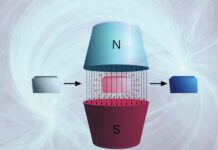

To guarantee that items are kept in ideal conditions, contemporary cold chain systems place a high priority on real-time temperature and humidity monitoring. IoT devices and sophisticated sensors are essential to this as shown in the Figure.

Conclusions

Industrial refrigeration in terms of cold storage business is experiencing a technological renaissance. By embracing innovative design, smart technologies, and sustainable practices, HVAC industry can create more efficient, environmentally friendly, and cost-effective storage solutions to make the cold supply chain better.

Dr. (Prof.) D. B. Jani received Ph.D. in Thermal Science (Mechanical Engineering) from Indian Institute of Technology (IIT) Roorkee. Currently he is a recognized Ph.D. Supervisor at Gujarat Technological University (GTU). He has published more than 280 Research Articles in reputed International Conferences and Journals. He has also published 25 reputed books/book chapters and patents in area of thermal engineering. He has been working as an Academic Editor for the Journal of Materials Science Research and Reviews. Presently, he is an Associate Professor at GEC, Bhavnagar, Gujarat Technological University, GTU, Ahmedabad (Education Department, State of Gujarat, India). He has obtained his Master of Engineering in Automobile Engineering from Gujarat University, Ahmedabad, Gujarat. He has more than 26 years of experience in teaching at various institutions at undergraduate and postgraduate/PhD level in mechanical engineering. He is a life member in professional societies and bodies like ISTE, ISHRAE, MTTF, REST, Green ThinkerZ etc. He is a recipient of Best Teacher award (2020), Excellent researcher award (2020), Innovative academician award (2024). His area of research is Desiccant cooling, ANN, TRNSYS, and Exergy.