Farmers suicide in our country especially in Maharashtra has become a burning issue since last two decades. Waiver of loans, compensation by government, free electricity etc. are not at all solutions for these problems.

Crop planning, proper storage till the product reaches market at appropriate time and value addition of agro produce mostly using renewable energy is the only solution.

In this article we shall discuss about the economical methods for cold storage based on renewable energy sources for the agro produce, which will help the farmer to hold it till good price can be fetched in the market.

In India alone, 10 million tonnes of cold storage capacity is required to prevent the over 30 per cent wastage of fruits and vegetables and other perishables. The main challenging task is transporting the produce to the far away located cold storage unit which involves substantial expenses for a short duration.

Considering the above challenges, adoption of renewable energy based mobile cold storage can be useful. Being a mobile unit, the system can be shifted to any site of any farm for cooling and storage of produce immediately after harvest. Further, it operates 100 per cent on renewable energy i.e. solar PV + battery storage + ice banking with or without solar thermal or biomass based methanisation or gasification.

A mobile cold storage does not depend on grid supply or back-up DG set and other infrastructure leading to huge cost saving at initial stage as well as in regular operations. As a result, it is best suitable for energy starved areas.

With a wide range of temperature control, it makes ideally adaptable for storing fruits, vegetables, flowers and other perishable agricultural produce.

If the fresh fruits and vegetables are stored at the temperature below their optimum low requirement, develop chilling injury and therefore, loose the marketability. The fruits stored at low temperature exhibit more shelf life than those stored at ambient temperature.

Mature green fruits may be stored at 10-degree C – 14-degree C for 30 days and ripe tomatoes at 4.5-degree C for 10 days under 85-90 per cent relative humidity. Fresh unshelled peas may be kept for two weeks at 32-degree F at relative humidity of 85-90 per cent. Peas can also be stored in crushed ice for about 2-3 weeks.

Storage mix

- Apples or pears with celery, cabbage, carrots, potatoes or onions.

- Celery with onions or carrots.

- Citrus with strongly scented vegetables.

- Pears/apples with potatoes as former acquire unpleasant taste.

- Green pepper will taint pineapples.

- Onions, nuts, citrus, potatoes should be stored separately.

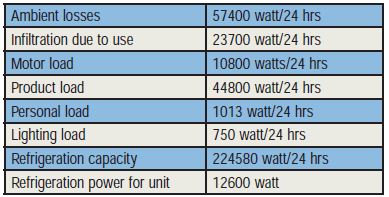

Construction of mobile cold storage unit

Insulation 60 mm thick PUF panel shall be provided for insulating the cold room walls and ceiling and flooring. For strengthening the insulation, chicken wire mesh is provided with it. The entire system is mounted on a trolley similar to used with tractor which is having dimensions as shown in the drawing.

R 404A refrigerant is used for the cooling unit. Room temperature of 2-degree C to 8-degree C should be maintained inside the chamber. The ambient temperature will be 40-degree C. The total refrigerant capacity will be 60,000 BTU/hr for 20 MT capacity cool chamber.

The storage life of fruits and vegetables even at low temperatures in general varies between 2 to 4 weeks excepting for a few commodities like apples, oranges, potatoes, cabbage etc. In case of cold room, long-term storage is not envisaged and duration of storage is likely to be 1 to 4 weeks.

Cold storage is the widely practiced method for bulk handling of the perishables between production and marketing processing. It is one of the methods of preserving perishable commodities in fresh and wholesome state for a longer period by controlling temperature and humidity within the storage system. Maintaining adequately low temperature is critical, as otherwise it will cause chilling injury to the produce. Also, relative humidity of the storeroom should be kept as high as 80-90 per cent for most of the perishables, below (or) above which his detrimental effect on the keeping quality of the produce. Most fruits and vegetables have a very limited life after harvest if held at normal harvesting temperatures. Post-harvest cooling rapidly removes field heat, allowing longer storage periods.

Proper post-harvest cooling can:

- Reduce respiratory activity and degradation by enzymes.

- Reduce internal water loss and wilting.

- Slow or inhibit the growth of decay-producing microorganisms.

- Reduce the production of the natural ripening agent, ethylene.

In addition to helping maintain quality, post-harvest cooling also provides marketing flexibility by allowing the grower to sell produce at the most appropriate time. Having cooling and storage facilities makes it unnecessary to market the produce immediately after harvest. This can be an advantage to growers who supply restaurants and grocery stores or to small growers who want to assemble truckload lots for shipment. Post-harvest cooling is essential to deliver produce of the highest possible quality to the consumer.

Cold storage can be combined with storage in an environment with added of carbon dioxide, sulphur dioxide, etc. according to the nature of product to be preserved. The cold storage of dried or dehydrated vegetables in order to maintain vitamin C, storage temperature can be varied with storage time and can be at 0-10-degree C for a storage time of more than one year, with a relative humidity of 80-95 per cent. The cold storage of perishables has advanced noticeably in recent years, leading to better maintenance of organoleptic qualities, reduced spoilage, and longer shelf lives. These advances have resulted from joint action by physiologists to determine the requirements of fruit and vegetables, and by refrigerating specialists to design and run refrigerating machines accordingly.

Cold chain management in India has been accelerated in last decades to reduce post-harvest losses. However, most of the tropical and sub-tropical agricultural as well as horticultural produce goes in waste due to its perishable nature and improper cold chain management on-farm. Thus, apart from the large cold storage chambers for long-term storage, refrigeration system also required for on-farm or in production catchment for agricultural crops during short-term storage.

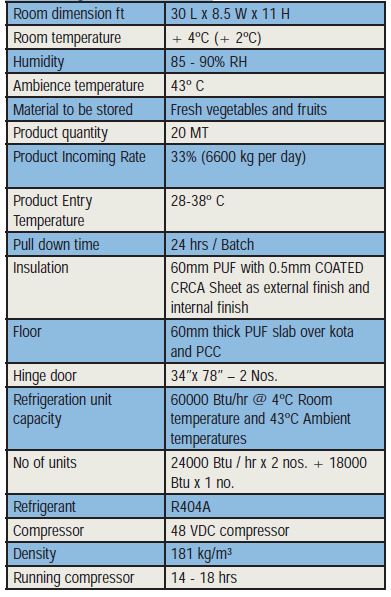

Basic Design 20MT Cold Room

Calculation Results

Perishable foods include fruits and vegetables, foods purchased from chill cabinets, freshly cooked food stored to be used later. It is usually stored in the refrigerator. Some fresh fruits and vegetables, however, will store quite well out of the refrigerator as long as they are stored in a cool place.

Good sound curds can be stored in cold storage for about a month at 30-degree F with 85-90 per cent relative humidity.

The low-pressure liquid refrigerant then allows passing through refrigerated space whereby the heat of hot air of refrigerated space starts evaporating the liquid refrigerant hence, heat in the atmosphere decrease and cooling is produced. Blowers circulates the chilled air to stored fruits and vegetables.

A general rule for vegetables is that cool-season crops should be stored at cooler temperatures (32 to 35-degree F), and warm-season crops should be stored at warmer temperatures (45 to 55-degree F). There are exceptions to this rule, though.

Cooling can be defined as the decrease of temperature of a substance or medium below temperature of its environment. Refrigeration is a process of lowering the temperature and maintaining it in a given space for the purpose of chilling foods, preserving certain substances, or providing an atmosphere conductive to bodily comfort. Storing perishable foods, pharmaceuticals, or other items under refrigeration is commonly known as cold storage. Such refrigeration checks both bacterial growth and adverse chemical reactions that occur in the normal atmosphere.

The most important factor in cold storage is ambient temperature. As a rule, the temperature in cold storage is higher than 2-degree C, which is the freezing point temperature of stored fruit and vegetable. Stored product must not be freezing in the cold storage reported that there is heat transfer in many places of cooling system and that the heat transfer widely takes place during the process.

The purpose of the calculation of cooling load is important choosing system components such as compressor, condenser etc. correctly and economically determination of all inputs of cooling load would not be possible, for this reason there may be some deviations in the cooling load and the focus point must be minimizing the deviation.

It is explained that the ambient temperature of cold storage, the situation of stored product before entering to the cold store, the daily working hours and the determination of which product will be stored are important for calculation of the cooling.

There is no method of defining cold store capacity that satisfies the requirements of everyone concerned with cold storage. Storage capacity based on the weight of produce that can be stored will depend on the storage density of the products and the method of storage.

Therefore, unless only one product is stored under closely defined conditions, this definition is obviously unsuitable. It is generally agreed that it is more appropriate to define storage capacity in terms of the store volume but there are a number of ways in expressing this value.

Gross volume is the volume of the refrigerated space whereas net volume is the volume that can potentially be used for storage and is the gross volume less the volume required for coolers, structural requirements, doorways and other permanent features of the store.

Effective volume is the store space that can actually be utilised for storage and it takes into account the requirements for passageways, stacking equipment etc.

Gross volume and net volume can easily be defined by devising a simple set of rules for making these calculations. These store volumes, however, can only give a rough estimate of storage capacity and their main use may before statistical purposes. The effective volume can only be calculated for each particular case and to achieve any degree of accuracy, a drawing of the store layout would be required together with full details of the storage conditions. Store operators should therefore use general statements of store capacity with care and when placing an order they would give full details of the products and the storage operation to enable the supplier to provide a store to suit the operating requirements with the maximum utilisation of the gross storage volume.

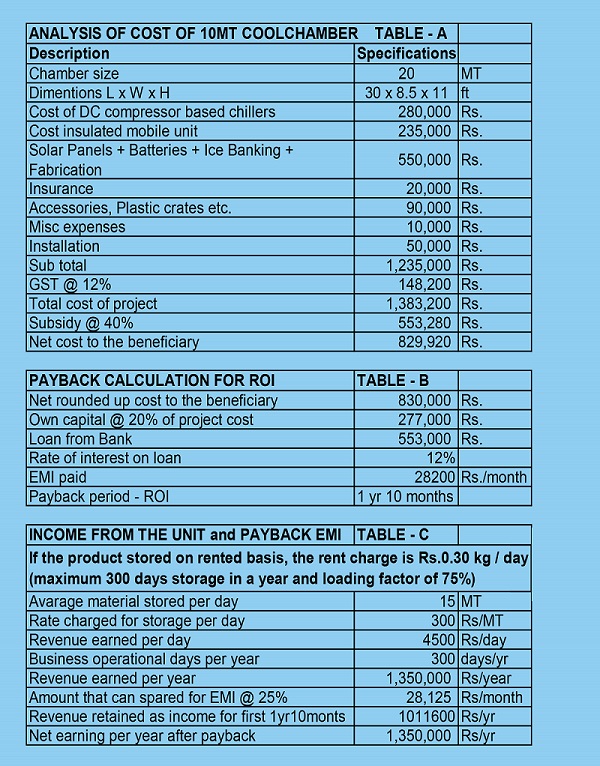

Costs are generally divided into three parts:

- Initial costs

- Annual fixed charges

- Operating costs.

Initial costs

- Cold storage built on a trolley with can hauled by any tractor

- Service charges for water, mobility to the site.

- Freezer plant

- Delivery charges

- Installation charges

- Design and consultation charges

- Refrigerant and oil charges.

Annual fixed costs

- Depreciation

- Interest

- Insurance

- Taxes

- Capital maintenance.

Operating costs

- Maintenance – refrigeration plant, building, handling

- Fuel – heating, electrical generator

- Water – condensers, washing, glazing, general refrigerant

- Oil

- Labour – freezer operation, handling, supervision, office

- EMI costs

- Social dues.

Factors to be observed

Care and Cleanliness

Close attention to care and cleanliness will minimise loss of quality, and the risk of introducing food poisoning micro-organisms.

Good handling practice should begin on board fishing vessels and be carried through to consumption. The fish should be stowed as soon as possible after catching, but always in a clean condition. Guts, trash fish, etc., should be kept separate and not allowed to contaminate fish for storage or processing. Offal and refuse should be kept away from processed fish and there should be an adequate system of disposal. All plant and equipment, fish rooms, containers, tables, etc., should be designed for case of cleaning, and they should preferably be made of non-corroding, washable material, especially, where in contact with fish. They should be kept clean by frequent washing. Care must be taken in the choice of cleaning and sterilising materials and methods.

Personnel should be trained to understand the causes of food poisoning and to practise high standards of hygiene. Coughing, sneezing, spitting, smoking and some minor injuries are potentially dangerous. Proper toilet and washing facilities are essential. Suitable clothing must be worn and kept clean. Personnel should be medically free from diseases.

All facilities and operations should be checked regularly with regard to care and cleanliness. The importance of high hygienic standards at the cold store cannot be overemphasised. In order to assure that storage facilities are continuously maintained in a manner which satisfy both company and regulatory agency standards and regulations, a store quality assistance audit should be scheduled on a regular basis and followed point by point. Obviously, such a programme must take local requirements into consideration.

Personnel Working in Cold Stores

Working in a cold store means exposure to extreme cold and demands high physical and mental standards. Heat losses from the body must be minimised by proper clothing. In addition, working in a low temperature environment creates special effect on the human body, which must be counteracted by a special working routine and provisions for personal welfare. As for anybody else working in the food industry, the employees must undergo regular checks and maintain the necessary level of personal hygiene required for this industry.

Among the initial effects of exposure to low temperatures are numbness in the fingers and toes and reduction in dexterity. Muscular activity and increased metabolism would help to maintain the body temperature around 37-degree C. On average, the heat dissipated by a man in W/min varies according to the physical activity e.g. at rest 1.5, light work 2.5-3, moderate work 4.5-5 and hard work 8. Shivering is the principal mechanism of the body to momentarily increase its metabolism, but a shivering worker becomes ineffective, when the heat losses are greater than the heat generation, the body temperature will continue to fall and thus, causes unsatisfactory physical response. It is usually considered that the metabolism will decrease by 12 per cent for every 1-degree C decrease of the body temperature. The lungs begin to freeze at about (-) 53-degree C. The human body will lose liquid through cold when exposed to low temperature. However, working in a low temperature environment is not hazardous to health, provided the worker is physically fit, i.e., submits himself to the necessary medical examination before employment and uses all the precautionary measures provided by the cold store properly.

Protective clothing

The term clo was introduced in order to define the insulating quality of clothing assembly. By definition, one clo will provide thermal comfort to a man sitting in an ambient of 21-degree C, 50 per cent relative humidity and 0.1 m/s air velocity. A long suit corresponds roughly to one clo, a linen suit to 0.8 clo, and a woollen suit under which is waistcoat, shirt and underclothes to 1.3-1.5. One clo is equal to 0.18-degree C m2 h/kcal. In polar climates 3 clos generally are considered suitable for moderate activity in a (-) 20-degree C ambient with a low wind velocity. However, this relates to selected individuals and for similar conditions in a cold store a value of 4 clos may be considered necessary.

Alarms

An acoustic alarm system must be provided for anyone who is accidentally locked up in a low-temperature room or for an injured person who cannot open the doors. The switches for the alarm should preferably be placed by every door and not more than 0.5 m from the floor. Other places for alarms are gangways around evaporators, roofs, engine room, etc. The sounder should be positioned where there is always someone in attendance, e.g., the loading bank or in the reception office.

Fire alarm systems are normally placed outside the cold rooms (to allow anyone to escape before raising the alarm). The alarm should sound both inside and outside the storage chambers. Automatic systems and smoke detectors are normally not a good alternative inside the low temperature rooms due to frosting up and reacting on to warm, moist air, etc.

Safety instructions

Safety instructions must be issued to all employees and cover emergencies such as fire, refrigerant leaks, escape doors, assembling points, etc. The instructions should be written in simple language and kept brief and to the point.

Hygiene

Keep your workplace, wash-room, shower and toilet clean and use the facilities available. Cleanliness promotes health and comfort. Play your own part in maintaining healthy conditions and do all you can to encourage others to do the same.

An accurate cost can only be determined for each individual case since so many factors have to be considered which depend on local conditions and economics.