The HVAC (Heating, Ventilation, and Air Conditioning) industry depends on a wide variety of fans and blowers for air management, climate control, and maintaining indoor air quality. Below is a comprehensive overview of the primary fan types used in modern HVAC systems, their principles of operation, and their benefits.

Axial Flow Fans

Working Principle

Axial flow fans move air or gas along the axis of rotation – meaning airflow is parallel to the fan’s shaft. Their design includes multiple propeller-like blades attached to a central hub, powered by a motor. As the blades rotate, they create a pressure differential that draws air from one side and propels it out the other, in a straight, axial line.

Key Features and Applications

- High Airflow and Energy Efficiency: Axial fans are capable of moving large volumes of air with minimal power consumption, making them ideal for general ventilation, cooling, and exhaust applications in large open spaces.

- Compact Design: Their simple construction allows installation in tight spaces, such as ducts and wall-mounted settings.

- Primary Uses: They are found in ventilation systems, cooling towers, condenser and chiller fans, and are also used in building exhaust and data centre cooling.

- Advantages: Quiet operation, versatile applications, and low maintenance needs.

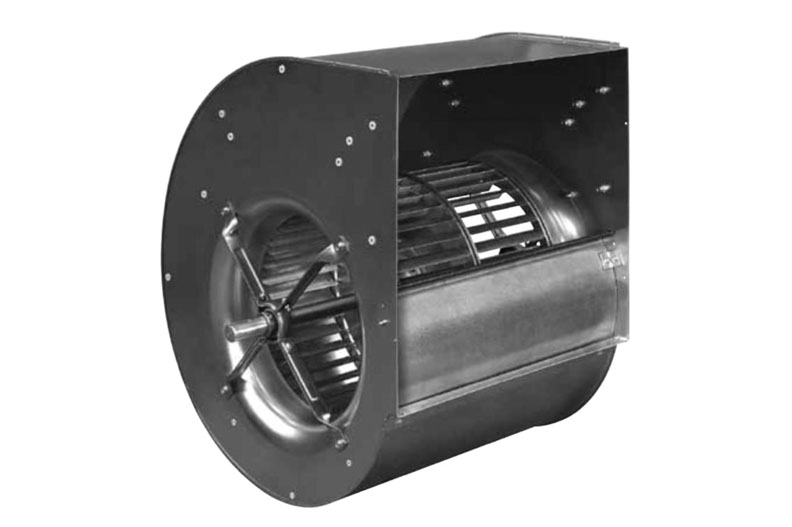

DIDW Centrifugal Fans (Double Inlet, Double Width: Forward & Backward Curved)

Design and Function

- Double Inlet, Double Width (DIDW): These centrifugal fans feature two air inlets and a wide impeller, essentially combining two single-width fans into one. This setup offers twice the airflow compared to single inlet fans for a given pressure.

- Forward Curved Blades: These fans have impeller blades that curve in the direction of rotation. They are ideal for applications that require high air volume at low to moderate pressure, running at lower speeds and generating less noise.

- Backward Curved Blades: With blades that curve against the direction of rotation, these fans are more efficient at handling higher static pressures and maintain a non-overloading power characteristic. They are commonly used where energy efficiency and reliability are paramount.

Applications

HVAC air handling units, supply and exhaust systems, ventilation in commercial, industrial, and process environments.

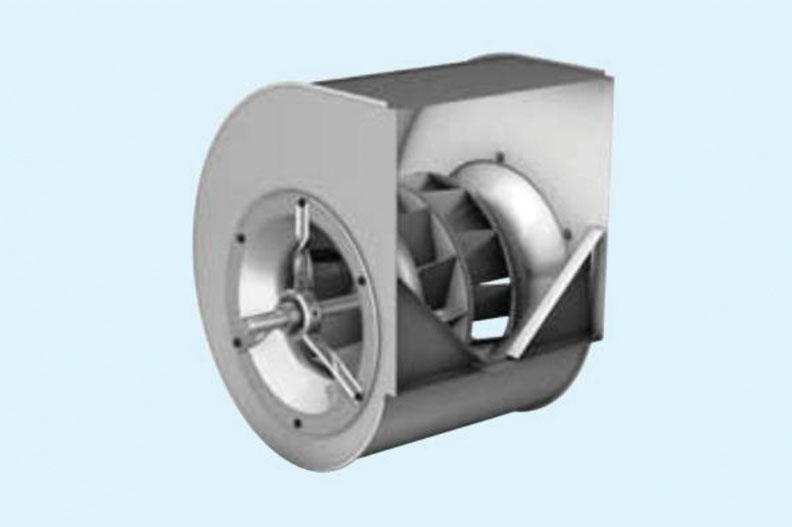

SISW Centrifugal Fans (Single Inlet, Single Width)

Description

SISW centrifugal fans have a single air inlet and a single-width impeller. These fans are robust, provide high efficiency at moderate air volumes and low to medium pressure, and are favoured for their compact footprint and ease of maintenance.

Applications and Benefits

- Commonly used in residential and industrial HVAC systems.

- Suitable for dust/fume extraction, clean rooms, laboratories, and material handling.

- Advantages include high efficiency, quiet operation, and durable construction.

Plug Fans

Overview

Plug fans, also known as plenum fans, are centrifugal fans with exposed, backward-inclined blades mounted directly on the motor shaft inside the Air Handling Unit (AHU) housing. This direct-drive design eliminates the need for belts and pulleys, reducing maintenance and improving overall efficiency.

Key Features

- High efficiency for low to moderate static pressure needs.

- Easy installation/removal and flexible configuration for AHUs.

- Widely used where customizable airflow and compact installation are crucial, such as clean rooms, pharmaceutical, and lab HVAC systems.

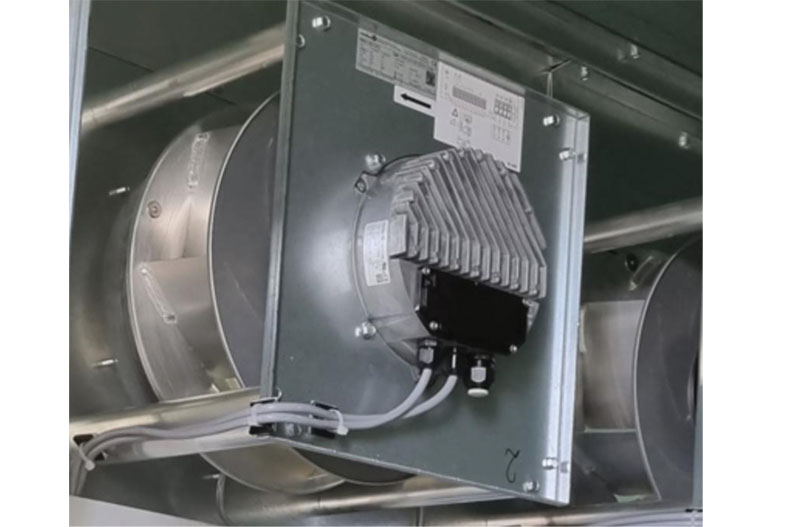

EC (Electronically Commutated) Fans

What Are EC Fans?

EC fans use brushless DC motors with integrated onboard electronics, providing precise speed control and greatly enhanced energy efficiency. They can achieve efficiencies up to 90%, generate less heat, and have a longer operational life compared to conventional AC fans.

Advantages

- Energy Savings: Dynamic speed control reduces power consumption, especially part-load.

- Quiet Operation: Improved aerodynamics and electronic commutation minimize noise.

- Plug-and-Play: Retrofit compatibility with many AC fan applications.

- Reduced Maintenance: Fewer moving parts and integrated electronics result in lower maintenance costs.

Applications

Modern HVAC systems, data centers, refrigeration units, medical devices, and advanced air handling units.

Industry Example: Modern AHUs with Advanced Fans

Companies like Brightflow Engineers integrate advanced, modern fans – including centrifugal (DIDW and SISW), plug, and EC fans – across their Air Handling Unit (AHU) product range.

Brightflow’s solutions focus on reliability, energy efficiency, and customisation, ensuring optimal airflow, pressurisation, and filtration based on client requirements. Their use of state-of-the-art fans highlights the HVAC industry’s shift toward smarter, more sustainable air management technologies.

Driving operational excellence in the HVAC sector, Aman Taluja is a pivotal professional at Brightflow Engineers Pvt. Ltd., Kundli, a Haryana-based leader in manufacturing Air Handling Units, Evaporative Cooling Units, Dry Scrubbers, and Fan Coil Units. His impressive track record spans successful installations for prestigious clients such as NTPC Dadri, Deloitte Gurugram, Le Meridien Hyderabad, Marriott Amritsar, and GAIL, Dibiyapur.