Despite its promising appearance, the Vapour Absorption Systems (VASs) technology is still in its early stage of development – and has numerous unresolved problems. The characteristics of different cycles have been evaluated from the perspectives of the ideal cycle CoP (Coefficient of Performance) and their applications. This article has attempted to cover all the pertinent aspects for future developments of vapour absorption refrigeration systems. For waste heat utilisation and the use of renewable energy sources for performance enhancement, absorption cycles may be coupled with other cycles and power generation cycles.

Absorption refrigeration systems are based on extensive development and experience in early years of refrigeration industry, particularly in ice production. Refrigeration industries are blamed for ozone depletion and global warming. Future development of refrigeration systems with its serious implications on environmental causes is a major concern.

The first major environmental concern is depletion of ozone layer by the emission of manmade chemicals into the atmosphere by refrigeration industries. Second major concern is global warming. This did not appear as a major issue till depletion of ozone layer was known.

An alternative with huge potential

The absorption refrigeration technology is a potential alternative to conventional VCRS that has drawn attention of scientists and engineers in recent years. The absorption refrigeration technology is a thermally powered refrigeration technique that uses heat energy, which can be taken from any low-grade energy reservoir or solar energy to provide cooling – such as the exhaust of IC engine. The generator, pump, absorber, solution heat exchanger, condenser, expansion valves and evaporator are the various components combined to form a VAS.

The refrigeration industry is well aware of the impact of refrigerants’ vapour released to the atmosphere. The new idea for reducing energy waste comprises not only an optimisation of energy use – but also lowering consumption. Besides, these goals must be achieved without compromising comfort.

Other advantages include the use of heat energy without affecting efficiency and quality of installations. The use of heat operated refrigeration systems helps in reducing problems related to global environment – such as the so-called greenhouse effect from CO2 (Carbon Dioxide) emission from the combustion of fossil fuels in utility power plants. The application of absorption refrigeration system reduces the electricity consumption as compared to the conventional refrigeration systems, but long-established compression systems still dominate the market. Promoting the use of ammonia-water refrigeration systems necessitates the improvement of system performance.

Working principle of absorption system

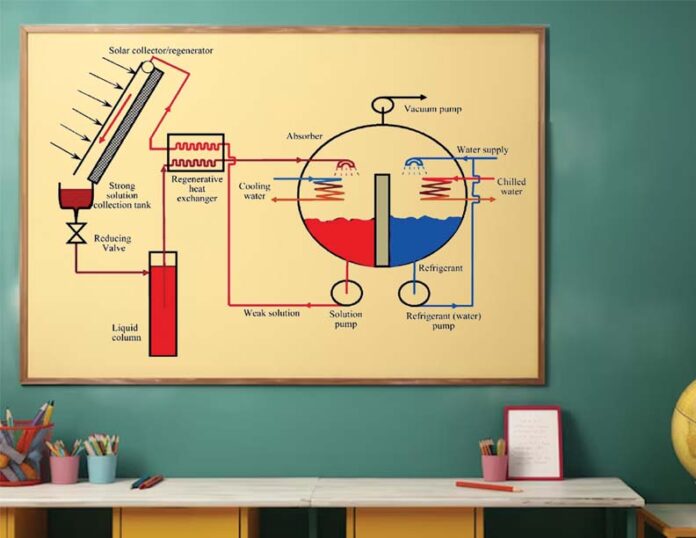

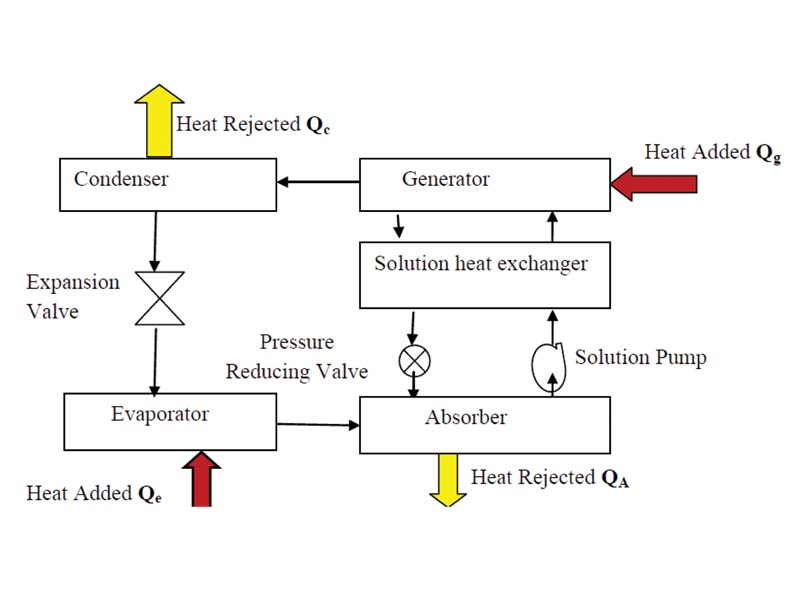

A basic vapour absorption cycle is a two-pressures and three-temperatures level cycle that makes use of a liquid, which can be easily converted into vapour as the refrigerant – and a second liquid as an absorbent. It consists of a generator, a condenser, an absorber, an evaporator, a solution pump, expansion valve and pressure reducing valve as shown in Fig.1.

Input energy is used to heat the generator and as work to the solution pump. The solution temperatures in the generator and absorber are not uniform due to the variation in solution concentration from inlet to outlet in these components. This causes heat transfer irreversibilities in addition to those due to internal mass exchange.

Similarly, the solution leaving the absorber is heated to the level of the generator temperature. A solution heat exchanger can be used to transfer the heat from the weak solution leaving the generator and strong solution leaving the absorber. This reduces the input heat required in the generator. This internal heat recovery improves the CoP.

In the vapour absorption refrigeration system, a physicochemical process replaces the mechanical process of the vapour compression refrigeration system by using energy in the form of heat rather than mechanical work. The main advantage of this system lies in the opportunity of utilising waste heat energy from industrial processes or other sources like solar energy as an energy input.

The vapour absorption refrigeration systems have many encouraging characteristics. Typically, a much smaller electrical input is required to drive the solution pump, compared to the power requirements of the compressor in the vapour compression system. Also, fewer moving parts means slower noise levels, higher reliability, and improved durability in the VAR systems (Vapour Absorption Refrigeration systems).

Working fluids in VAS

The efficiency of an absorption cycle is determined not only by the cycle design, but also by the working fluid used in the cycle. Performance of an absorption refrigeration system is critically dependent on the chemical and thermodynamic properties of the working fluid. A fundamental requirement of absorbent-refrigerant combination is that, in liquid phase, they must have a margin of miscibility within the operating temperature range of the cycle.

The mixture should also be chemically stable, non-toxic, and non-explosive. Therefore, the working fluid is an important subject in order to improve the efficiency of absorption cycles. For absorption refrigerators, the following pairs are frequently employed:

1) NH3/H2O

2) H2O/H2O-LiBr

3) CH3OH/CH3OH-salt solution

4) R22 (CHCIF2)/E181 or other organic solvent

5) R134a (CH2CICF3)/ETFE

Among the working fluids, H2O/H2O-LiBr and NH3/NH3-H2O are the most widely used ones in proprietary absorption refrigerators. This is because these two working-pairs have so far provided the best energy performances compared to others. However, the water-LiBr solution is corrosive at high temperatures and crystallisation occurs at high concentrations.

Water as the refrigerant also freezes at sub-zero temperatures, which limit its applications. Although the ammonia-water pair does not crystallise and could work at sub-zero temperatures, the volatility of water with ammonia and the high vapour-pressure of the solution result in increased complexity of construction and high cost. In addition, the efficiency of the ammonia-water systems is lower than that of the LiBr-water system.

Hybrid VAS cycle

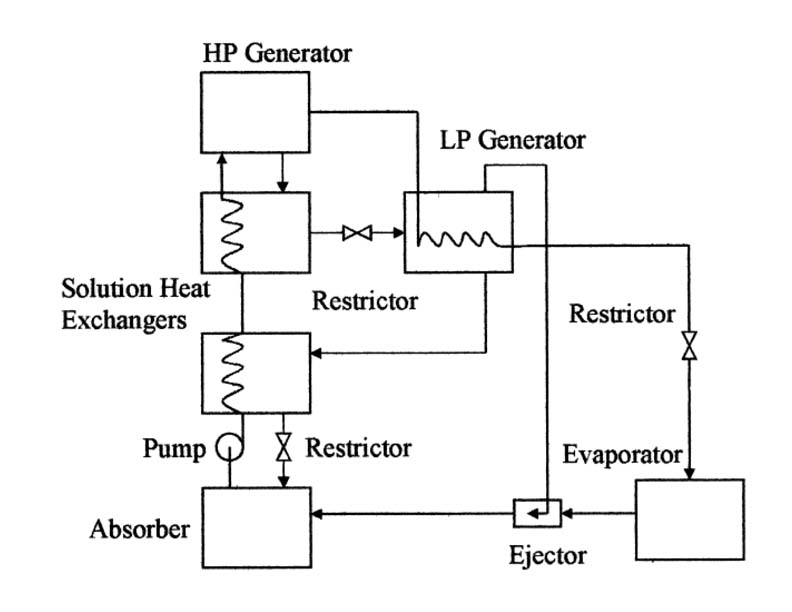

Using an ejector as a compressor in absorption cycles is an innovative way of combining the vapour absorption cycles with the vapour compression cycles, and this approach avoids the use of mechanical work. The ejector function in the absorption cycles can be classified in three ways, i.e., to enhance the evaporation process, to enhance the absorption process and to enhance the concentration process.

The hybrid cycle that uses an ejector to entrain the vapour from the evaporator and discharges it to the absorber, is shown in Fig. 2.

In the cycle, the ejector is driven by vapour from the low-pressure generator of a double-effect absorption cycle. This cycle increases the temperature lift and eliminates the need for a condenser, but the CoP is not improved.

However, this system can only be operated using a high-density refrigerant vapour, because a liquid driven ejector is not suitable for low-density vapour – such as water vapour as used in water-LiBr absorption cycles. The ejector cycle is driven by water vapour from the generator of the absorption cycle. Because the steam ejector utilises the energy, otherwise lost in a conventional absorption cycle, to enhance the vapourisation process in this novel cycle, a higher CoP is expected.

Trends and future applications of VAS

With respect to the trends in absorption machines, research and development of new working fluids is a never-ending subject of interest. The advantages of capable binary, ternary and quaternary salt mixtures are discussed thoroughly in working fluids.

Lower efficiency and cost of absorption machine are still some burning issues. These are the reasons why a lot of research work is focused on enhancing the heat and mass transfer in order to improve the performance.

Further efficiency improvement and importance of inexpensive, compact components (compact heat exchangers) are pointed out. The developments in solar energy collection and transferring technology has produced the meaningful impact on absorption technology. The focus is more on system integration. How to integrate absorption machines in complex, poly-generation systems in the most efficient way. This further implies the interest in optimisation.

A good control strategy of the absorption machine and whole system is essential. Combination of absorption technology with other technologies may be performed by using various applications. However, combination with absorption does not assure that these applications would be efficient and able to compete with other technologies, in particular with conventional vapour compression technology. The absorption becomes attractive in specific applications where there are possibilities to use waste heat or thermal energy from renewable energy sources. Some of specific applications where absorption technology may be beneficial are:

- Where there is a large amount of thermal energy generated through solar collectors or waste energy is usually discarded from industrial processes; in facilities that have concurrent need for heat and power.

- In cases where electricity supply is unpredictable, costly or where absorption can help to decrease peak loads.

- In cases where governmental policies support the use of clean energy. The absorption technology is the most profuse in two types of applications: solar assisted systems for refrigeration and poly-generation systems.

Conclusions

The potential of the field of primary energy savings and environmental benefits are the main advantages that encourage further development of absorption systems. Reduced electricity consumption and low CO2 emission have been confirmed by many researchers.

At the end, all the facts mentioned above indicate that absorption systems have a good potential for further development under the emerging renewable energy technologies, but a lot of research work to be incorporated ahead. Appropriate standards, test procedures and best-practice guides together with intensified work on simulations, optimisation and control strategies improvement are some of the needs, which are necessary to accelerate the progress to compete with conventional systems.

Hybrid absorption-cycles provide an alternative way to improve the energy efficiency of absorption heat-pumps. Since mechanical compressors require high-grade energy to drive them, the hybrid absorption cycles using mechanical compressors lose the ability to utilise low-grade heat sources, which is one of the most important features of the absorption cycle.

Dr. (Prof.) D. B. Jani received Ph.D. in Thermal Science (Mechanical Engineering) from Indian Institute of Technology (IIT) Roorkee. Currently he is a recognized Ph.D. Supervisor at Gujarat Technological University (GTU). He has published more than 250 Research Articles in reputed International Conferences and Journals. He has also published 10 reputed books and book chapters in the area of thermal engineering. He is an Academic Editor for the Journal of Materials Science Research and Reviews. Presently, he is an Associate Professor at GEC, Bhavnagar, Gujarat Technological University, GTU, Ahmedabad (Education Department, State of Gujarat, India). His area of research is Desiccant Cooling, ANN, TRNSYS, and Exergy.