Refrigerants are vital to modern life because they make refrigeration, Air Conditioning (AC), and heat pump systems work efficiently. These systems are necessary for industrial processing, medical applications, indoor climate control, and food preservation. These materials facilitate the transfer of thermal energy in heating and cooling systems by absorbing and releasing heat through phase changes.

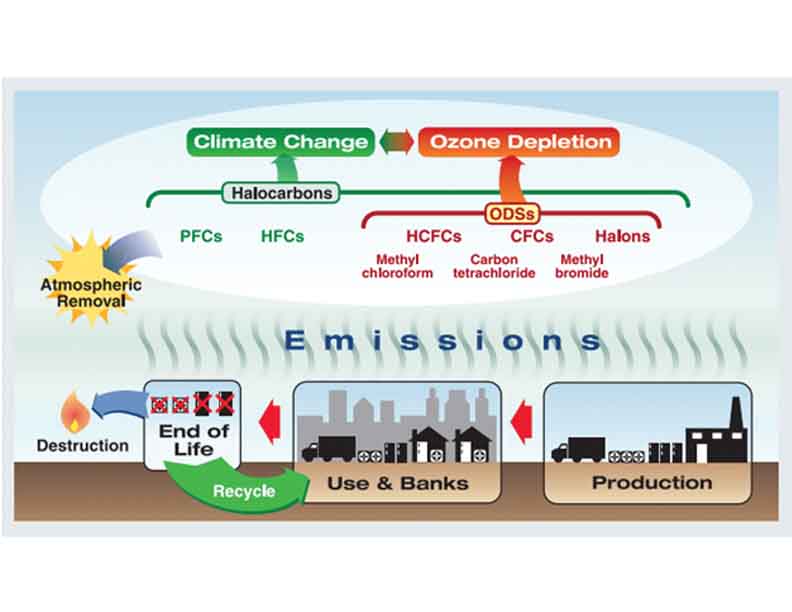

Because of their chemical stability, non-flammability, and compatibility with system components, Chlorofluorocarbons (CFCs) and Hydrochlorofluorocarbons (HCFCs) were the most commonly used refrigerants in the past. But these advantages came at a high cost to the environment. According to research conducted in the latter half of the

20th century, CFCs and HCFCs significantly contributed to the depletion of the ozone layer, which increased the amount of Ultraviolet (UV) radiation that reached the Earth’s surface. Furthermore, a large number of these refrigerants had a high Global Warming Potential (GWP), which means that they could accelerate climate change by trapping heat in the atmosphere thousands of times more effectively than carbon dioxide (CO₂).

International environmental protocols, such as the Montreal Protocol and its amendments (such as the Kigali Amendment), have responded by requiring the gradual reduction of high-GWP refrigerants and the phase-out of substances that deplete the ozone layer. This has sparked a major change in the HVAC (Heating, Ventilation, Air Conditioning, and Refrigeration) sector towards the use of contemporary refrigerants that are safer for the climate and the ozone layer.

Natural substitutes like ammonia, carbon dioxide, and hydrocarbons, as well as contemporary refrigerants like Hydrofluoroolefins (HFOs), are currently being given priority. These materials are designed or chosen to provide drastically lower greenhouse gas emissions, low or zero Ozone Depletion Potential, and frequently higher energy efficiency. The wider use of these more recent refrigerants in residential and commercial applications has also been made possible by improvements in system design, safety regulations, and regulatory compliance.

The switch to contemporary refrigerants is a global environmental necessity as well as a technological one. In order to maintain the advantages of air conditioning and refrigeration without endangering the health of our planet, it demonstrates a larger commitment to sustainable development, energy efficiency, and climate action.

Evolution of Refrigerants

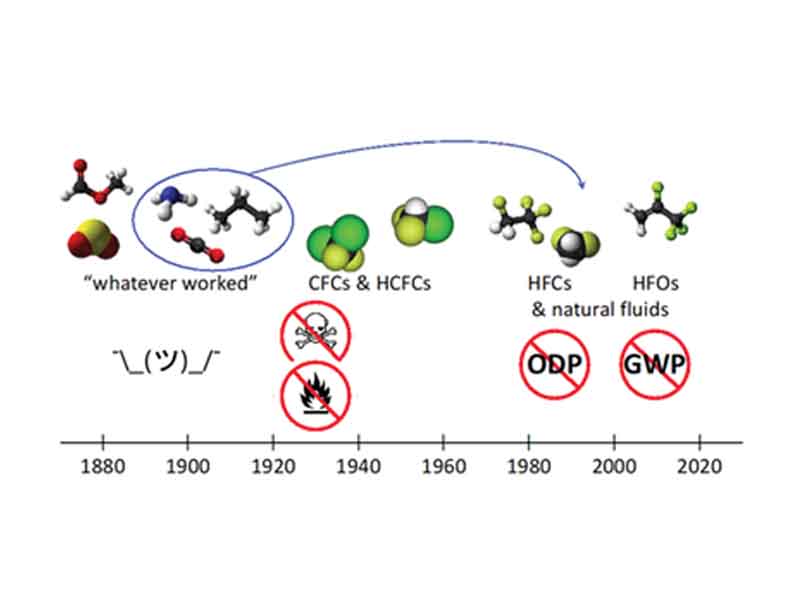

First Generation: Natural Refrigerants

During the late 19th and early 20th centuries, the early development of refrigeration technology relied on natural refrigerants such as ammonia (NH₃), carbon dioxide (CO₂), and hydrocarbons like propane (R-290) and isobutane (R-600a). These substances were selected for their excellent thermodynamic properties, availability, and low environmental impact.

- Ammonia was widely used in industrial refrigeration due to its high efficiency, but its toxicity and flammability presented safety concerns, particularly in residential applications.

- Carbon dioxide was non-toxic and non-flammable but required very high operating pressures, limiting its use until recent advancements in technology made it more viable.

- Hydrocarbons like propane and isobutane offered good performance and negligible ozone depletion or global warming potential, but their high flammability restricted their widespread adoption, especially in urban or enclosed environments.

Despite the challenges, these refrigerants are regaining popularity today due to renewed interest in low-GWP, environmentally friendly alternatives.

Second Generation: CFCs and HCFCs

The refrigeration industry began using synthetic refrigerants, mainly Hydrochlorofluorocarbons (HCFCs) and Chlorofluorocarbons (CFCs), in the middle of the 20th century. These included compounds like R-12 (CFC-12) and R-22 (HCFC-22), which at the time had several benefits. They were chemically stable, non-toxic, and non-flammable, which made them perfect for a variety of applications ranging from large HVAC systems to home refrigerators.

Their extensive use changed modern living and industrial processes by aiding in the mass commercialisation of air conditioning and refrigeration.

Later research revealed that these substances weaken the stratospheric ozone layer, especially as a result of the chlorine atoms released by CFCs and HCFCs.

International efforts to phase them out resulted from this, most notably the 1987 Montreal Protocol, which required the worldwide reduction and ultimate eradication of Ozone-Depleting Substances (ODS).

Third Generation: HFCs

To replace ozone-depleting CFCs and HCFCs, the industry transitioned to hydrofluorocarbons (HFCs) such as R-134a, R-410A, and R-407C. These refrigerants:

- Contain no chlorine, which means they have zero ozone depletion potential (ODP).

- They are generally non-flammable, non-toxic, and stable, making them suitable for a variety of commercial, residential, and automotive applications.

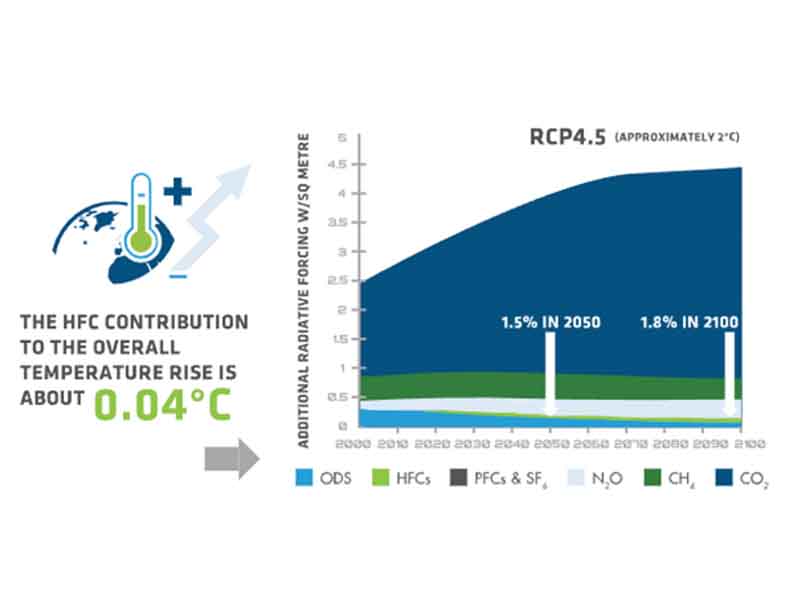

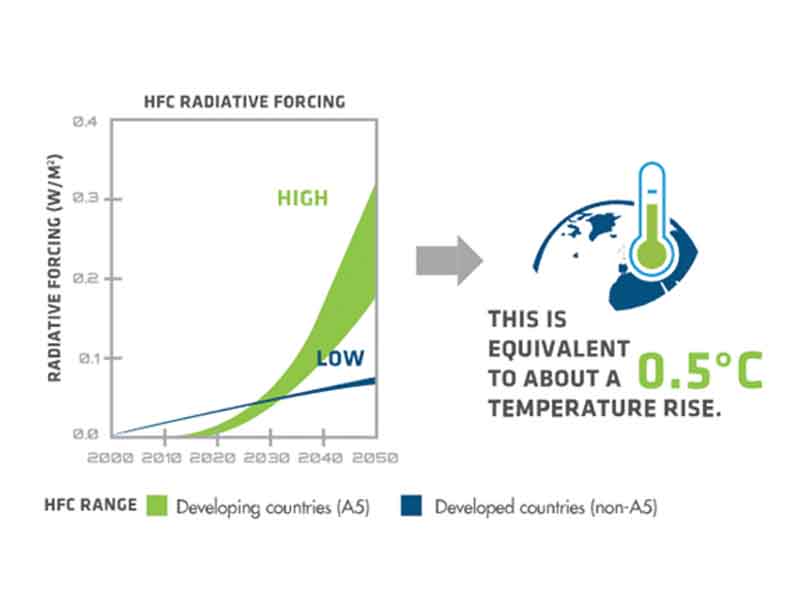

However, HFCs were later found to have very high Global Warming Potentials (GWPs) for example, R-134a has a GWP of approximately 1,430, and R-410A around 2,088. Their increasing use began contributing significantly to climate change.

In response, the Kigali Amendment to the Montreal Protocol was adopted in 2016, setting a global framework for the phasedown of HFCs to curb their climate impact.

As a result, current industry trends are moving toward the development and adoption of fourth-generation refrigerants – such as HFOs (hydrofluoroolefins) and natural refrigerants – that offer low GWP, energy efficiency, and compliance with environmental regulations.

Modern Refrigerants: An Overview

With the global shift toward environmental sustainability, the HVAC&R industry has introduced a new generation of refrigerants that are not only efficient but also comply with international climate goals. These modern refrigerants fall into three major categories: Hydrofluoroolefins (HFOs), natural refrigerants, and low-GWP blends.

Hydrofluoroolefins (HFOs)

Hydrofluoroolefins (HFOs) are the latest class of synthetic refrigerants developed to overcome the high Global Warming Potential (GWP) issues associated with Hydrofluorocarbons (HFCs). As unsaturated organic compounds with a short atmospheric lifetime, HFOs exhibit a GWP close to 1, comparable to that of carbon dioxide, making them a much more climate-friendly option. They feature zero Ozone Depletion Potential (ODP), ultra-low GWP, and are classified as non-toxic and mildly flammable (A2L safety class).

Additionally, HFOs often demonstrate good compatibility with existing HVAC systems, allowing for easier integration. Common HFOs include R-1234yf, widely used in automotive air conditioning as a replacement for R-134a, and R-1234ze(E), used in chillers, vending machines, and propellants. Blended HFOs such as R-513A and R-450A serve as drop-in alternatives in commercial refrigeration systems. Although typically more expensive and mildly flammable, HFOs are viewed as a key solution for sustainable cooling in the transition to low-emission technologies.

Natural Refrigerants

Natural refrigerants are substances that exist naturally in the environment and are gaining popularity in modern refrigeration systems due to their minimal environmental impact, strong thermodynamic performance, and increasing regulatory support. The main types include ammonia (R-717), carbon dioxide (R-744), and hydrocarbons such as propane (R-290) and isobutane (R-600a).

Ammonia is commonly used in industrial cold storage, food processing, and ice rinks, offering high energy efficiency, low cost, and zero GWP, though its toxicity and corrosiveness restrict its use to systems operated by trained personnel. Carbon dioxide is applied in supermarkets, heat pumps, and transport refrigeration, valued for being non-toxic, non-flammable, low-cost, and having a GWP of just 1; however, it operates under high pressure, requiring specially designed equipment. Hydrocarbons are widely used in domestic refrigerators and small commercial units, offering excellent energy performance and very low GWP, though their high flammability limits their charge size.

Regulatory incentives and carbon reduction goals, especially in Europe and Asia, are accelerating the adoption of these natural refrigerants as sustainable alternatives to synthetic options.

Low-GWP Synthetic Blends

To facilitate the transition from high-GWP HFCs, manufacturers have developed blended refrigerants that combine Hydrofluoroolefins (HFOs) and Hydrofluorocarbons (HFCs), aiming to balance performance, safety, and environmental impact while serving as drop-in replacements for existing systems.

Notable examples include R-32, a single-component refrigerant with a GWP of approximately 675, commonly used as a lower-GWP alternative to R-410A in split air conditioning systems. R-452B and R-454B are newer blends specifically designed to replace R-410A in air conditioning systems, offering improved environmental profiles. R-513A, a blend of R-134a and R-1234yf, provides a 56% reduction in GWP compared to R-134a and is widely used in chillers and commercial refrigeration. These blended refrigerants enable incremental improvements in climate impact and allow for smoother adoption in existing infrastructure without requiring significant modifications to HVAC equipment.

Applications of Modern Refrigerants

The adoption of modern refrigerants spans across various domains – from residential air conditioning to large-scale industrial refrigeration. Each application sector has its unique requirements for safety, efficiency, cost, and environmental compliance.

Residential and Commercial Air Conditioning

In order to cool homes, workplaces, and commercial buildings, refrigerants are used in residential and commercial air conditioning systems, which is one of their most common uses. Due to its higher energy efficiency and substantially lower Global Warming Potential (GWP) than R-410A, the industry standard, R-32 has become the preferred refrigerant for split-type air conditioners among the more recent options.

Despite this change, R-410A is still used in many systems today, and the move to lower-GWP alternatives is still ongoing. Blends like R-452B and R-454B, which provide better environmental performance while remaining compatible with existing system designs, are being introduced by manufacturers to support this shift.

Furthermore, blends based on HFO are being assessed for application in Variable Refrigerant Flow (VRF) and ducted systems, providing further options for low-GWP solutions. In all of these systems, energy efficiency and refrigerant safety – particularly the flammability classification (A2L) – are critical design considerations, balancing performance with risk management.

Automotive Air Conditioning

Strict environmental regulations, especially in the US and the EU, have caused a significant shift in the use of refrigerants in the automotive industry. In order to meet these regulations, automakers have mostly switched R-134a to R-1234yf in their new models. With a GWP of less than 1, R-1234yf has a significantly lower environmental impact while providing comparable cooling performance and efficiency.

Additionally, because of its non-flammable nature, superior heat transfer qualities, and efficiency in heat pump systems, R-744 (carbon dioxide) is being investigated more and more for use in Electric Vehicles (EVs), which need sophisticated thermal management systems for battery and cabin cooling.

Industrial Refrigeration

In the industrial sector, refrigeration systems are critical to operations in food processing, cold chain logistics, breweries, and pharmaceutical manufacturing. These large-scale applications demand high-capacity, reliable, and efficient refrigerants. Ammonia (R-717) remains the gold standard in industrial refrigeration thanks to its exceptional thermodynamic properties, energy efficiency, and low cost.

However, due to its toxicity and corrosiveness, its use is typically limited to systems managed by trained personnel. Meanwhile, Carbon Dioxide (R-744) is gaining ground through cascade and trans critical system designs, particularly in cold storage facilities and distribution centers, where it offers an environmentally friendly and effective solution, especially in colder climates. These systems are increasingly favoured as industries seek to reduce their carbon footprint without compromising performance.

Commercial Refrigeration (Supermarkets, Retail, Cold Rooms)

Stricter environmental regulations and the need for increased energy efficiency are driving a major transformation in the commercial refrigeration industry, which includes supermarkets, retail establishments, and cold rooms. Supermarkets and hypermarkets throughout Europe have embraced CO₂ (R-744) trans critical systems as a low-GWP, highly effective substitute for conventional refrigerants. These systems work particularly well in colder climates, and they are also being improved for warmer climates.

Hydrocarbon-based plug-in systems using R-290 (propane) and R-600a (isobutane) are becoming more and more popular in smaller retail applications like display cabinets, vending machines, and convenience store refrigerators because of their exceptional energy performance and extremely low GWP.

HFO blends like R-448A and R-449A are utilised in systems that were initially built for high-GWP refrigerants like R-404A. These refrigerants are mainly used in retrofit projects, offering a practical path to compliance without full system replacement. Retailers are now prioritising not only refrigerant choice but also the broader environmental footprint of their systems, focusing on reducing refrigerant leakage, optimising energy consumption, and ensuring long-term regulatory compliance across their refrigeration.

Regulatory Trends and Environmental Impact

Kigali Amendment and HFC Phase-Down

By focusing on the gradual phase-down of Hydrofluorocarbons (HFCs), powerful greenhouse gases with a high Global Warming Potential (GWP), the Kigali Amendment to the Montreal Protocol represents a significant international effort to mitigate climate change.

The global refrigeration and air conditioning industry is moving towards lower-GWP alternatives like Hydrofluoroolefins (HFOs), natural refrigerants, and low-GWP blends because of signatory nations’ mandatory adoption of structured timelines for reducing their production and consumption of HFCs. Globally, the development and uptake of environmentally friendly refrigerants are being accelerated by this regulatory change.

Energy Efficiency and Life Cycle Climate Performance (LCCP)

Environmental impact assessments are no longer limited to a refrigerant’s GWP alone. Increasingly, the industry is adopting Life Cycle Climate Performance (LCCP) metrics, which consider both direct emissions from refrigerant leakage and indirect emissions from energy consumption over a system’s operational lifetime.

This comprehensive approach emphasises the importance of energy-efficient system design alongside low-GWP refrigerant selection. Regulatory bodies and sustainability frameworks are integrating LCCP into compliance standards, pushing manufacturers and operators to optimise both refrigerant choice and system performance.

Challenges and Future Outlook

Safety Considerations

Safety is still a major concern as the industry switches to newer refrigerants. HFOs and hydrocarbons are among the many low-GWP refrigerants that are either toxic (like ammonia, B2) or mildly flammable (like A2L or A3). Strict adherence to safety regulations and standards, improved ventilation, flame arrestors, and leak detection are all necessary for their use. For engineers and equipment manufacturers, ensuring safe operation while maintaining high efficiency is a major challenge.

Training and Infrastructure

For HVAC&R professionals, switching to alternative refrigerants comes with a steep learning curve. Retraining is required for technicians to handle, install, and maintain systems that use high-pressure or flammable refrigerants safely.

In order to adapt to the characteristics of new refrigerants, storage facilities, charging apparatus, and service tools must also be updated. To facilitate this shift and guarantee workforce preparedness, governments and business associations are creating training curricula and certification programs.

Innovation in System Design

Innovation in the refrigeration sector is being propelled by the shift to low-GWP refrigerants. Manufacturers are rethinking system architecture and creating integrated leak detection technologies, high-efficiency compressors, microchannel condensers, and sophisticated heat exchangers to maximise performance and safety.

In order to meet changing performance standards and minimise environmental impact, these innovations are crucial. Additionally, the change is encouraging the creation of small, modular systems that can be used in a variety of contexts.

Conclusion

The global HVAC&R industry is undergoing a transformative shift toward modern refrigerants that are safer for the environment and more energy efficient. Hydrofluoroolefins (HFOs) and natural refrigerants such as CO₂, ammonia, and hydrocarbons are at the forefront of this movement, supported by international regulations like the Kigali Amendment and guided by life cycle climate performance criteria.

While there are still challenges related to safety, training, and infrastructure, ongoing innovation and collaboration across sectors are paving the way for a future of sustainable, climate-friendly refrigeration technologies.

Dipanwita Samaddar is a Subject Matter Expert – HVAC from ZURU Tech India Pvt. Ltd.