Moisture in food storage can cause frosted products and slippery floors. Employing cold storage dehumidification is crucial to prevent moisture buildup in food storage, especially in active ones where products are frequently moved, and different temperature zones are maintained for various goods such as ice cream, frozen foods, and fresh produce. This food storage dehumidification systems work by extracting excess moisture from the air, thereby reducing the risk of frost formation and ensuring safer working conditions. Furthermore, they help extend the shelf life of perishable items by maintaining optimal humidity levels.

Proper food storage dehumidification or cold room humidity control system is essential for preserving product quality and minimising losses due to spoilage in cold storage facilities. To combat moisture-related issues in active cold stores, efficient cold storage dehumidification systems are crucial.

A cold room dehumidifier effectively maintains optimal humidity levels, preventing ice buildup, and preserving product quality. By investing in advanced dehumidification technology, businesses can minimise downtime, reduce maintenance costs, and ensure a safe and efficient working environment within their cold storage facilities. In addition to investing in efficient food storage dehumidification systems, implementing proactive maintenance routines can further mitigate moisture-related challenges.

Regular inspection and cleaning of evaporator coils help prevent ice buildup and ensure optimal cooling efficiency. Moreover, sealing any gaps or cracks near loading docks can reduce the ingress of moist air, minimising fog formation and frost buildup in these areas.

Additionally, educating staff on proper handling and storage practices can help mitigate moisture absorption by cardboard cartons, reducing the risk of product damage and workplace hazards. By adopting a comprehensive approach to moisture management, businesses can optimise the performance of their cold storage facilities and safeguard both their products and employees.

Benefits of dehumidification in food storage

The role of dehumidification in the food industry is larger than one can probably think of. It is seen at the food and beverage industry processes at various stages. Maintaining low humidity and RH levels is a must to reduce spoilage, and ensuring optimal food freshness before it reaches the consumers. But, there are a few other benefits of using dehumidifiers for food industry such as:

- Preserving quality of food: There are many stages that the food industry deals with like processing, drying, storing, and packaging of raw foods, vegetables, and fruits before they are finally produced before the consumers. So, the need to control temperature and humidity is a must – especially, in the back drop of the Indian tropical climate. Thus, dehumidification for food acts as a guardian to maintain supreme food quality. Which otherwise can deteriorate due to excess humidity. It not only enhances the taste, texture, and food quality. But also, helps in minimising spoilage and rejects.

- Prevention of fungal growth: The formation of water droplets due to high moisture in the air invites fungus and other harmful bacteria into the food processing units. HVAC based dehumidifiers for food industry can create a safe place for you to process food without the fear of contamination. As dehumidifiers reduce humidity conditions by maintaining precise climate control. So that, the foods can be stored for longer duration without molds and mildew affecting the quality of processed foods.

- Increase the self-life of food: Temperature control in food industry directly correlates with the shelf life of stored foods. Especially, for hygroscopic food products like potato and starch-based foods, require low levels of humidity to maintain their shape and freshness. I know that it is not always possible for you to control and operate humidity levels inside the premises of your food industry. That is why, a dehumidifier can benefit you by drying the air indoors and reducing the excessive moisture content from the air. Thus, it can see that the stored food items for a longer period with lesser spoilage.

- Meets standard regulatory compliance: The food industry has to deal with strict food guidelines and regulations before passing the final products to the consumers or marketplace. If any food processing unit does not pass the quality check process due to compromised food quality. Then, it needs to discard the entire food batch, which will not only cost a hefty amount but also repeated rejections would tarnish brand value in the global and national food industry.

Therefore, a dehumidifier makes sure that your food items are processed, stored, and manufactured in optimal climatic conditions – so that excessive moisture and humid air cannot affect your food items. So, use of HVAC dehumidifiers for food industry can be a cost-effective solution to adhere to regulatory compliances.

- To maintain consistency in food characteristics: The production output of specific food items like confectionaries, cereals, flour, and sugar requires consistent low-temperature to maintain its shape, flavour, texture, and richness. Thus, use of a dehumidifier provides ideal humidity. It also increases indoor air quality throughout the food production units to enhance production capacity by controlling the characteristics of food items.

- Prevention due to corrosion damage: Condensed water often settles on large surfaces of pipelines and fittings that cold water flows through. The lower the temperatures are on these surfaces; the more condensation risks increase. The consequences of this can be far-reaching and consequently costly. Over a time, the permanent exposure to moisture causes corrosion to build up in the affected areas.

Worse still, depending on where the piping systems are located, the condensed water can also enter production or storage tanks and cause considerable damage to equipment and product. The use of dehumidification systems based on adsorption technologies prevents condensation, corrosion and mold formation. Thus, preventing permanent damage to products and production facilities.

- Minimal downtime: An essential component of process quality is an unimpeded, consistently efficient production flow of the conveyor and transport. If their environment is not sufficiently dehumidified can result in product buildup, sticking to conveyor belts or clogging of conveyor paths caused by lump formation. This can severely disrupt the production process. Intelligent dehumidification solutions offer food manufacturers optimal control and management of their processes.

- Maintain hygienic, efficient conditions: Corrosion damage, wood rot, and fungal growth are just a few of the ways an environment with high relative humidity can hinder food processing applications. On the other hand, conditions that are too dry introduce problems such as packaging brittleness, reduced airborne infection control when an employee is sick as aerosols will spread further, and electrostatic discharges that can damage equipment.

Staying within the ideal RH range for your application is crucial if you wish to avoid these complications. Using humidifier and dehumidifier technologies together to regulate conditions helps employees focus and become more productive, reduce downtime and absenteeism, and minimise product wastage while boosting quality assurance. This can mean considerable cost savings when managing products in bulk or running a large-scale operation.

Other benefits of dehumidification for food processing purposes include:

- Keeps condensation under control while ensuring product freshness

- Manages water vapour accumulation and regulates relative humidity parameters

- Ensures a clean, hygienic, and safe working environment for employees

- Cuts down on product, material, and time wastage

- Standardises quality and operational efficiency for improved cost control

- Ensures consistent quality and production efficiency for sensitive goods such as products that require strict hygroscopic conditions

Rather than focusing on the difference between humidification and dehumidification, the most beneficial approach is to make full use of these separate processes.

Use of dryers in food storage

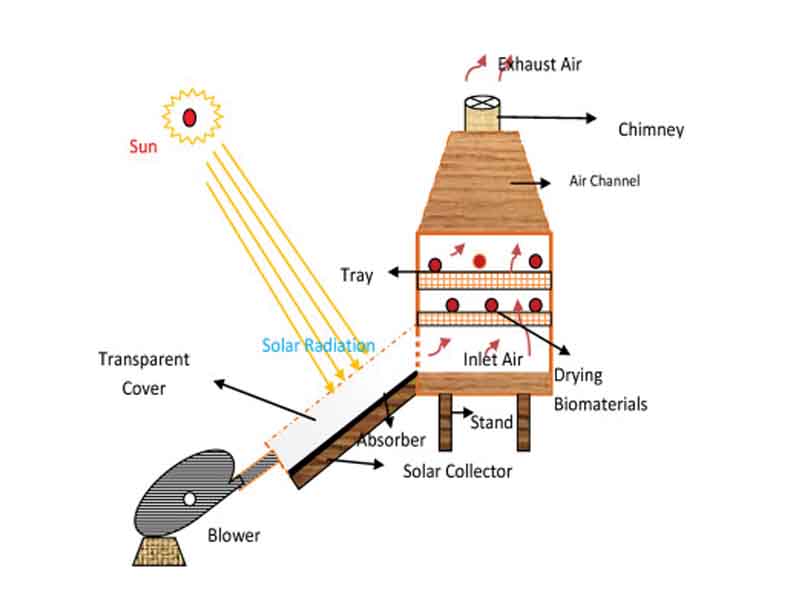

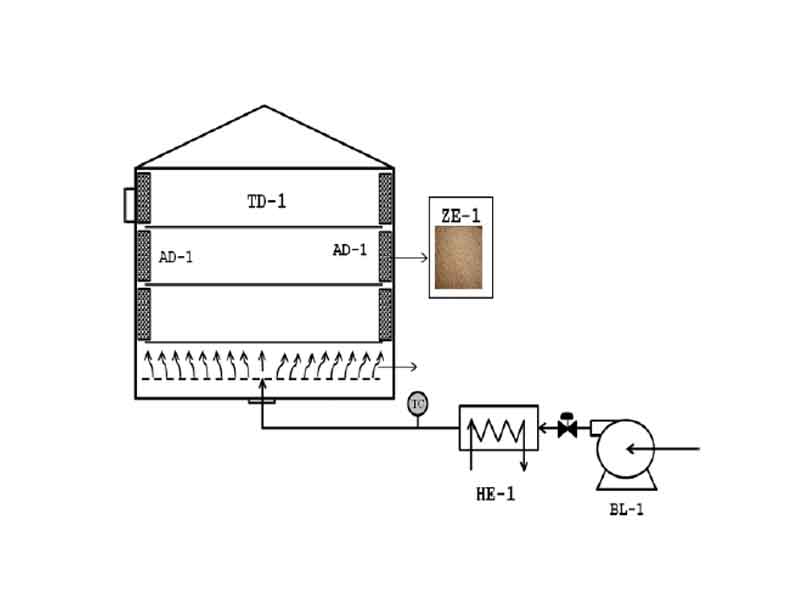

Storage of foods like onion was harvested from a farm with 90 – 95% moisture content. After drying, the average moisture content in the onion was desired to be 75 – 85%. The onion drying was conducted in tray dryer completed with zeolite, as presented in Figure 1. The fresh air was heated up to 50°C by a conventional electric heater. The air was used for onion drying with addition of a zeolite pack. After evaporating the moisture from wet onion, the hot-wet air was dehumidified by zeolite. The steps were repeated for different air temperature and air velocity.

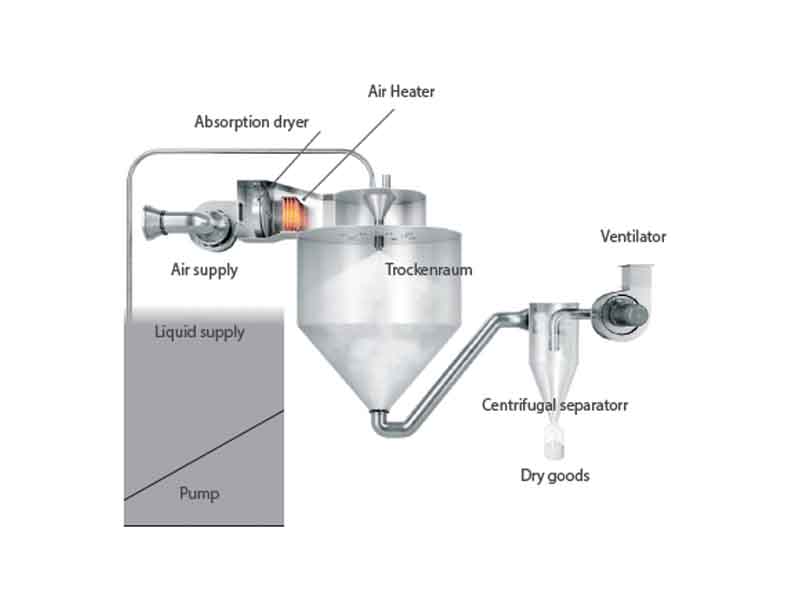

Spray-drying is commonly used in the food industry where liquid products are turned into powders as shown in Figure 2. These are either then sold as finished goods or are used as basic substances for the production of other products. Spray dried products include powdered milk and instant coffee.

In the manufacture of powdered milk, the process of spray-drying completely removes the water from the milk. Milk powder is commonly used in the manufacturing of cheese, yogurt, confectionery particularly chocolate and baked goods; it is also a major constituent of instant baby food. The process of spray drying is employed in the production of, many other food powders and is used extensively in the pharmaceutical industry.

When labelling bottled beverages, excessive humidity in the vicinity of production can damage the label of the filled bottles. The problem is: When the cool, filled and labelled bottles are brought into the warehouse, there is a risk of condensation on the bottle surface. This can have a disastrous effect on the adhesive of the label through softening, causing loss of adhesion and the label slips off the bottle. This problem can be prevented by dehumidification at the storage and labeling locations. Whether there is mold on the corners and edges or the labels are unusable due to creasing, slipping or peeling: The use of current and efficient dehumidification technologies effectively prevents these problems.

Cookies, potato chips, and pretzels that are stored in the open for a certain period of time lose their ‘crunch’ or crispness – they draw moisture from the ambient air and absorb it. In baked goods that consist primarily of the hygroscopic ingredients; such as flour and suga, the desired properties can be ensured by air humidity management. Wherever bread is baked and stored, i.e., in bakeries or, even more extensively, in the industrial production of baked goods, the use of effective dehumidification systems serves to maintain the appropriate product quality and prevention of mold formation.

Adsorption drying

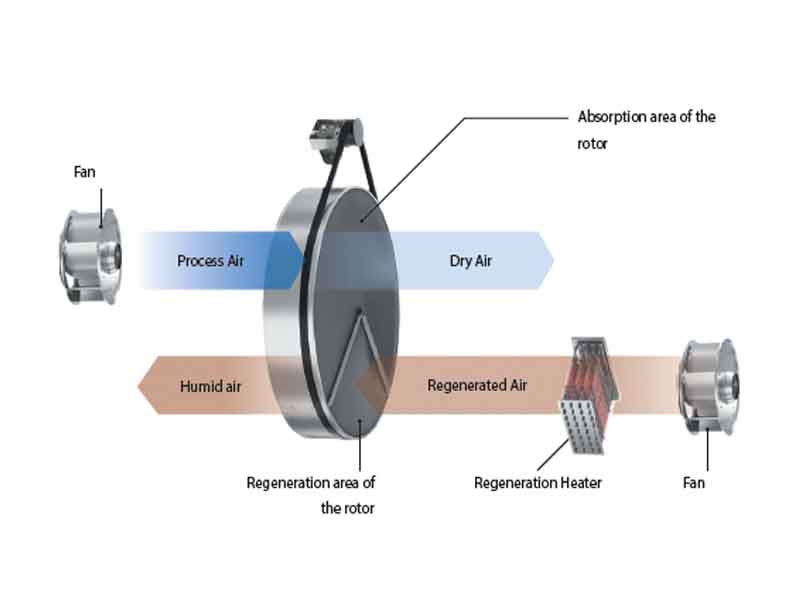

Adsorption dryers are used when a moisture content of less than about 45% RH is required, often at very low temperatures. In this application, condensing dehumidification of the air would be too costly and energy-intensive. An adsorption dryer consists of a sorption rotor, air filters, two fans for conveying the process air and the regeneration air, a heater for heating the regeneration air and the associated control system (see figure 3). The use of Adsorption dryers is not limited to humidity levels below 45% or applications at low temperature. Any form of condensing dehumidifier will typically give control in the order of +/-10% either side of set point. Whereas desiccant adsorption driers will control to +/-2% RH.

Two processes take place simultaneously as the air flows through the sorption rotor: The process air can be dehumidified effectively. However, depending on the intensity of dehumidification, the air temperature may rise significantly. Therefore, it is often necessary to cool the now dehumidified but warm air before returning it to the room. For this dehumidification process to work, the sorption rotor must be continuously regenerated: This means that the moisture stored in the silica gel must be constantly removed from it.

This is done with regeneration air, which flows through the sorption rotor from the other side in countercurrent. The regeneration air is heated, and consequently the relative humidity drops so much that it is sufficient to expel the water from the silica gel and bind it as steam in the air (desorption). The now humid regeneration air leaves the adsorption dryer and, if necessary, after a supplementary heat recovery, is blown out to the outside air. Hot water, steam, gas burner or electrical energy is used as media for heating the regeneration air.

Conclusions

The use of HVAC dehumidifiers for food storage industry has evolved over time, with more people acknowledging to its varied benefits in the dominant industry of foods and beverages. Thus, embracing the dehumidification system is no longer an option. But, a strategic and essential move in sustaining food products to meet consumer needs.

Dr. (Prof.) D.B. Jani received Ph.D. in Thermal Science (Mechanical Engineering) from Indian Institute of Technology (IIT) Roorkee. Currently he is a recognized Ph.D. Supervisor at Gujarat Technological University (GTU). He has published more than 280 Research Articles in reputed International Conferences and Journals. He has also published 25 reputed books/book chapters and patents in area of thermal engineering. He is also working as Academic Editor for the Journal of Materials Science Research and Reviews. Presently, he is an Associate Professor at GEC, Bhavnagar, Gujarat Technological University, GTU, Ahmedabad (Education Department, State of Gujarat, India). He has obtained his Master of Engineering in Automobile Engineering from Gujarat University, Ahmedabad, Gujarat. He has more than 26 years of experience in teaching at various institutions at undergraduate and postgraduate/PhD level in mechanical engineering. He is a life member in professional societies and bodies like ISTE, ISHRAE, MTTF, REST, Green ThinkerZ etc. He is a recipient of Best Teacher award (2020), Excellent researcher award (2020), Innovative academician award (2024). His area of research is Desiccant cooling, ANN, TRNSYS, and Exergy.