Before we explore the concept of sub-ISO Class 1 Cleanrooms, which are cleaner than ISO Class 1 Cleanrooms, we will first take an overview of the history of cleanrooms, air filtration systems, etc.

Overview of the history of air filtration systems

In the 1820s, the smoke helmet was invented, which had a personal air filter for occupational safety.

In the 1850s, the charcoal-based filter mask was invented.

In the 1860s, rudimentary air filtration systems for hospitals were introduced.

In the 1870s, the original firefighter masks created during the 1820s were upgraded, introducing a respirator to aid in the breathing for firefighters.

In the 1900s, the world’s first spray-type air conditioning equipment, able to both filter and humidify or dehumidify air was invented.

In the 1920s, there was commercialisation and innovation in industrial air filtration systems.

In the 1930s, a combined mechanical blower and air purifier unit – called the collective protector – was developed. It was equipped with cellulose-asbestos paper in deep-pleated form with spacers between the pleats. The paper was referred to as an ‘absolute air filter’ and it was the precursor to what would later become the HEPA (High Efficiency Particulate Air) filter.

In the 1940s, the first HEPA filter was developed (it was not called HEPA until the 1950s).

In the 1950s, the absolute filter technology was declassified and commercialised & multiple companies started manufacturing them.

In the 1960s, the generic acronym ‘HEPA filter’ was coined for these filters.

In the late 1970s, ULPA (Ultra Low Particulate Air) filters started to be developed.

Overview of the history of cleanrooms

Hospitals were the first spaces to attempt to control the air where patients were located.

From the 1860s till the 1950s, hospitals started experimenting with mechanical ventilation systems.

In the 1950s, one of the first unidirectional airflow rooms using sterile air supply and displacement ventilation were built.

In the 1960s, modern cleanrooms were developed.

From the 1960s till the 1980s, cleanrooms were developed & they incorporated HEPA filters in their HVAC systems.

From the 1990s, higher classes of cleanrooms came into being due to the development of ULPA filters.

Classification of cleanrooms

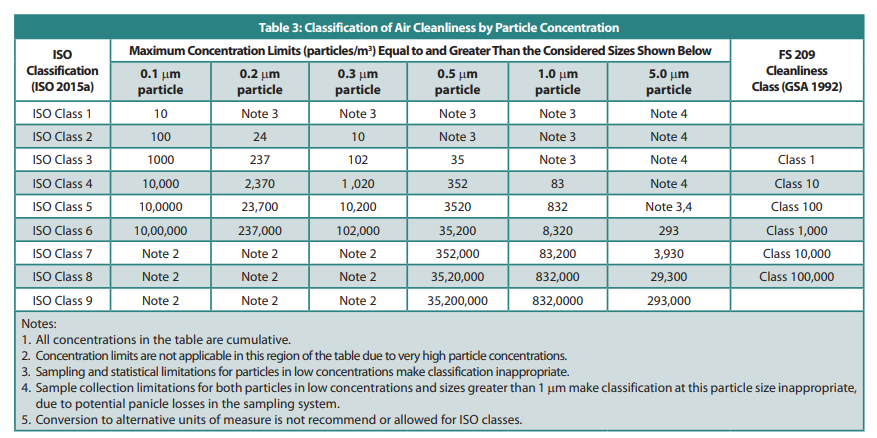

Currently, cleanrooms are classified as per ISO 14644 from classes 1 to 9. ISO Class 1 & 9 cleanrooms are the highest and lowest grade cleanrooms respectively.

Classification of air filters

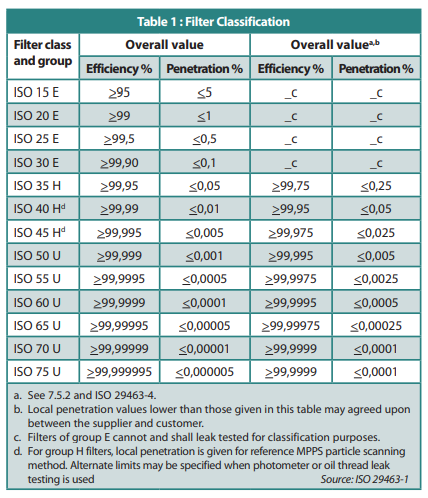

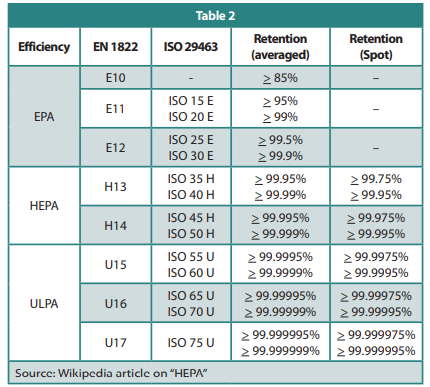

Presently, air filters are classified as per the MERV rating system from 1 to 20, in which MERV 1 & 20 filters are the lowest & highest-grade filters respectively. They are also classified as per ISO 29463 as given in the table below.

For air filters of lower grades than HEPA & ULPA filters, the MERV rating system from 1 to 16 is used. The ISO 29463 rating system gives more classes of EPA (Efficient Particulate Air), HEPA & ULPA filters than the MERV rating system from 17 to 20.

Retrospectively, the gradual development of HVAC systems and air filters before the advent of HEPA filters and cleanrooms led to the establishment of climate control systems in which temperature and humidity control was done and particle control to some extent was helpful in the attempt to development clean spaces in hospitals and factories. However, the development of HEPA filters initially and ULPA filters later, along with airflow control led to the successful development of cleanrooms.

Sub-ISO Class 1 cleanrooms

Cleanrooms; which could be cleaner beyond ISO Class 1 cleanrooms, let’s call them sub-ISO Class 1 cleanrooms; are not officially classified as such at present. ISO Class 0 cleanrooms as a theoretical concept (not officially classified by the ISO) would mean zero particles in the cleanroom, which is not possible.

Developing a sub-ISO Class 1 cleanroom would mean having less than 10 particles of 0.1 μm size in the room.

There are two ways in which particles can enter the cleanroom:

- From outside the cleanroom by infiltration and through HVAC systems.

- From inside the cleanroom, i.e., particle generation from the personnel, equipment, cleanroom materials for walls, panels, floor, furniture, etc.

Now, if a particular cleanroom under consideration is under negative pressure w.r.t. the adjacent rooms or outside surroundings, then infiltration cannot be prevented, although it is unlikely that this room will be a sub-ISO Class 1 cleanroom.

Currently, the highest grade ULPA filter ‘ISO 75 U’ has an averaged retention rate ≥ 99.999995%. To construct & operate a cleanroom way beyond ISO Class 1 cleanroom, an ULPA filter having an averaged retention rate even greater than 99.999995% would be necessary to be developed.

Reducing the level of activity of personnel to reduce particle shedding, designing production processes in such a way that Particle Generation Rate (PGR) is reduced, choosing cleanroom materials having low PGR might help to some extent but it won’t be enough in this case.

Need & ways to develop sub-ISO Class 1 cleanrooms

In semiconductor manufacturing plants, the environment that wafers are exposed to has reached the current limits of ISO 14644-1. The semiconductor industry seeks wafer environments that are cleaner than ISO Class 1 spaces.

Emerging nanomaterials are expected to revolutionise cleanroom environments and semiconductor fabrication techniques. Traditional silicon-based materials are approaching their physical limits, necessitating the adoption of 2D materials such as graphene, Transition Metal Dichalcogenides (TMDs), and Carbon Nanotubes (CNTs) for next-generation transistors. These materials require even more stringent contamination control, as atomic-scale impurities can drastically impact electronic properties.

To accommodate these new materials, cleanrooms must evolve by integrating more advanced filtration and purification systems capable of maintaining molecular-level cleanliness. Research in nanofabrication – compatible air filtration and plasma – based contamination removal is expected to enhance particle control and reduce Airborne Molecular Contamination (AMC) risks in semiconductor cleanrooms.

Robotics plays a crucial role in reducing human contamination risks. Human operators are among the largest sources of particle contamination in cleanrooms, even when wearing full-body protective suits. Autonomous robots and robotic arms equipped with machine vision capabilities are now used for wafer handling, material transport, and equipment maintenance, significantly reducing human interaction in ultra-sensitive fabrication zones. These robots operate with micron-level precision, ensuring delicate semiconductor wafers remain free from contamination throughout the production cycle. Moreover, Automated Guided Vehicles (AGVs) have become essential in modern semiconductor fabs, enabling the safe and contamination-free transfer of wafers between fabrication tools.

Rushikesh Jog possesses a bachelor’s degree in mechanical engineering and a post-graduate diploma in HVAC. He is currently working as a Jr. HVAC Design Engineer and Business Development Assistant at Proficient, a pharmaceutical consultancy firm. Proficient provides various services such as pharmaceutical facility design, validation, Good Manufacturing Practices (GMPs) compliance, etc.