In most industries, HVAC systems are associated with human comfort. In the food and beverage industry, however, their function transcends comfort entirely. Here, HVAC is a mission-critical utility, a fundamental component of process control that directly safeguards food safety, ensures product quality, and upholds regulatory compliance.

A poorly designed or maintained HVAC system is not only an inconvenience; but also it’s a direct threat to public health and a company’s brand reputation. From raw material storage to final packaging, the air that touches the product is an ingredient. Controlling its temperature, humidity, and purity is paramount.

The Four Pillars of HVAC Control in Food Processing

Effective environmental control in a food facility rests on four key HVAC functions:

- Temperature Control: Precise temperature management is the first line of defence against spoilage and microbial growth. Different stages of food production require specific temperature ranges to maintain product integrity. For example, processing areas for raw meat or dairy must be kept cold to inhibit bacteria, while processes like baking or pasteurization require controlled heating. An optimised HVAC system ensures these precise temperatures are consistently maintained, preserving the freshness, taste, and shelf life of the final product.

- Humidity Control: Controlling moisture is arguably one of the most critical functions of HVAC in this sector.

- High Humidity: Excessive moisture leads to condensation on surfaces, creating an ideal breeding ground for mould, yeast, and dangerous bacteria like Listeria. This poses a severe risk of product contamination.

- Low Humidity: In contrast, insufficient humidity can cause products like baked goods or certain produce to dry out, negatively impacting their texture, quality, and weight.

A well-designed HVAC system actively manages relative humidity, removing excess moisture to prevent condensation while adding it where necessary to protect product integrity.

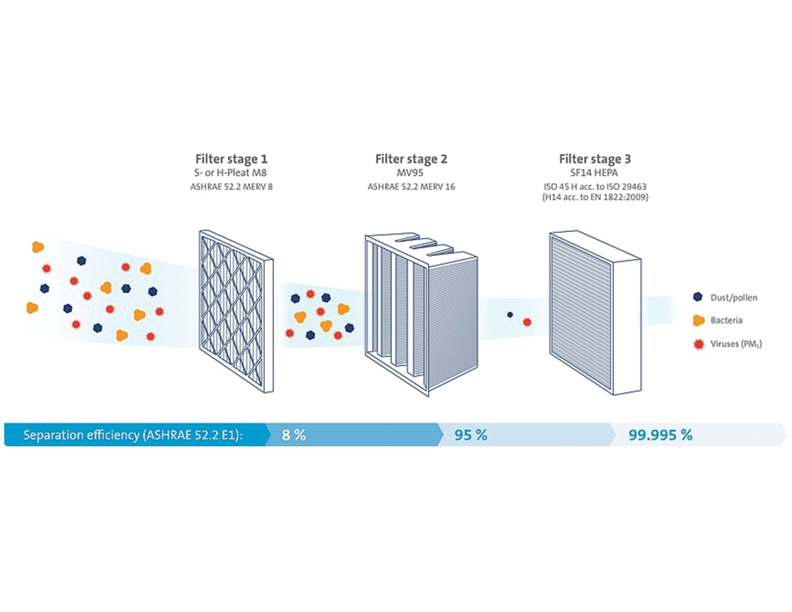

- Air Quality and Filtration: The air in a food processing plant can be filled with contaminants, including airborne bacteria, mould spores, dust from ingredients like flour, and allergens. HVAC systems are crucial for air purification. By using a multi-stage filtration strategy—often incorporating High-Efficiency Particulate Air (HEPA) filters—these systems can remove up to 99.97% of airborne particles, ensuring the air coming into contact with food is clean and safe. This filtration is vital for preventing cross-contamination between different processing zones.

- Airflow and Pressurisation: Proper airflow design ensures that filtered, conditioned air is distributed evenly throughout a space, eliminating ‘dead spots’ where contaminated air can stagnate. Furthermore, HVAC systems are used to create pressure differentials between rooms. High-care areas, like packaging zones, are kept at a higher positive pressure than adjacent, lower-care areas. This ensures that air always flows from the cleanest areas to less clean ones, preventing contaminants from entering critical zones.

Design Challenges Unique to the Food Industry

Designing an HVAC system for a food facility is far more complex than for a commercial office building. Engineers face several unique challenges:

- Strict Zoning Requirements: A single facility may have multiple zones with drastically different environmental needs—from refrigerated processing rooms and hot, humid cooking areas to dry storage and sanitised packaging rooms. The HVAC system must be designed to maintain these distinct conditions simultaneously without them negatively impacting one another.

- Aggressive Cleaning Protocols: Food processing facilities undergo frequent and intensive washdowns with high-pressure water and caustic chemicals. HVAC components, especially ductwork and air handlers, must be designed to withstand this harsh environment without corroding or harbouring microbial growth. Materials must be non-porous and easily cleanable.

- Condensation Management: Preventing condensation is a top priority. This requires careful management of surface temperatures and dew points. HVAC design must account for every variable, from the temperature of the concrete floor to the heat generated by processing equipment and personnel.

- Material Selection: Standard galvanised steel ductwork is often unsuitable. Materials like stainless steel or specialized fabrics are preferred. Ductwork must also be located away from open product lines to prevent any potential contaminants from dripping down.

Modern HVAC Solutions and Best Practices

To meet these challenges, the HVAC industry has developed specialised solutions for the food and beverage sector:

- Fabric Ducting Systems: An increasingly popular alternative to metal, fabric ductwork offers significant advantages. Its permeable surface provides even, draft-free air distribution, which eliminates cold spots where condensation could form. Many fabrics are inherently antimicrobial and can be easily taken down and commercially laundered, ensuring a higher level of hygiene than is possible with fixed metal ducts.

- Hygienic Air Handling Units (AHUs): Manufacturers such as Brightflow Engineers now offer AHUs specifically designed for food processing. These units feature stainless steel construction, smooth interior surfaces free of crevices where microbes could hide, easily accessible components for cleaning, and advanced filtration systems.

- Advanced Filtration and Purification: Beyond HEPA filters, systems may incorporate UV germicidal irradiation (UVGI) lights within the AHU or ductwork to kill airborne bacteria and mould, providing an extra layer of protection.

- Smart Controls and Energy Efficiency: Given that HVAC can account for 40-60% of a facility’s energy use, efficiency is key. Modern systems use Variable Frequency Drives (VFDs) on fans and motors, along with a network of sensors connected to a Central Building Management System (BMS). This allows for precise control over all environmental parameters while optimising energy consumption.

Regulatory Compliance: The Non-Negotiable Standard

A food facility’s HVAC system is a critical component for meeting stringent safety standards set by bodies like the FDA, USDA, and international organisations through frameworks like HACCP (Hazard Analysis and Critical Control Points) and GMP (Good Manufacturing Practices). These regulations mandate strict environmental controls, and a failure of the HVAC system to maintain these conditions can lead to failed audits, costly shutdowns, product recalls, and severe damage to a brand’s reputation.

Driving operational excellence in the HVAC sector, Aman Taluja is a pivotal professional at Brightflow Engineers Pvt. Ltd. Kundli, Haryana-based leader in manufacturing Air Handling Units, Evaporative Cooling Units, Dry Scrubbers, and Fan Coil Units. Aman’s impressive track record spans successful installations for prestigious clients such as NTPC Dadri, Deloitte Gurugram, Le Meridien Hyderabad, Marriott Amritsar, and GAIL Dibiyapur.