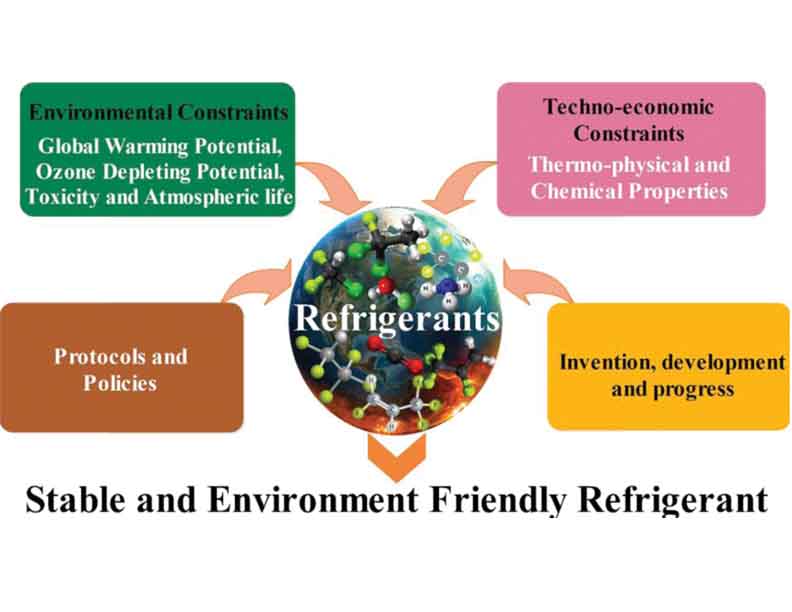

Refrigerants are chemical compounds used in HVAC systems to absorb heat from the environment and release it elsewhere, effectively controlling indoor temperatures. Without refrigerants, air conditioning and heating systems would be unable to function, leaving homes and offices uncomfortable. HVAC systems are designed to regulate the indoor environment of your home. These systems rely on a cycle of refrigeration to maintain the desired temperature and humidity levels. The refrigerant plays a crucial role in this cycle, allowing the system to absorb heat from inside your home and release it outside, or vice versa. The understanding of the role of refrigerants is particularly important. The hot and humid summers and mild winters in this region demand efficient HVAC systems to maintain comfort year-round. Using the right refrigerant can enhance the performance and longevity of your HVAC system, ensuring you stay comfortable in all seasons. Refrigerants can significantly impact the environment, primarily through ozone depletion and global warming potential.

- Ozone Depletion Potential (ODP): Some older refrigerants, like CFCs and HCFCs, contain chlorine, which can break down ozone molecules in the atmosphere. This reduces the ozone layer’s ability to block harmful ultraviolet radiation from the sun.

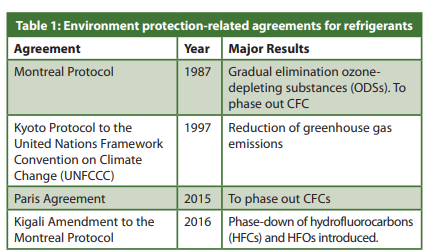

- Global Warming Potential (GWP): Many refrigerants, including some HFCs, are potent greenhouse gases. They can trap heat in the atmosphere, contributing to global warming. The GWP of a refrigerant indicates how much heat a gas can trap compared to carbon dioxide. Due to their environmental impact, refrigerants are subject to strict regulatory measures as shown in Table 1. The Montreal Protocol and subsequent amendments have mandated the phase-out of ozone-depleting substances. Newer regulations, such as those from the Environmental Protection Agency (EPA), are focusing on reducing the use of high-GWP refrigerants.

In addition to environmental considerations, the safety of refrigerants is of the utmost importance. Some conventional refrigerants are extremely toxic or combustible, posing hazards to human health and safety. To ensure safe operation in refrigeration and air conditioning systems, environmentally benign refrigerants should exhibit lower toxicity and lower flammability. The efficacy and performance of refrigeration and air conditioning systems are directly affected by the thermodynamic properties of refrigerants. To ensure efficient and dependable operation, environmentally friendly refrigerants must possess desirable thermodynamic properties, such as appropriate boiling and condensing temperatures, heat transfer coefficients, and volumetric capacity.

Environmental Impact of Traditional Refrigerants

The capacity of a material to obliterate ozone molecules in the stratosphere is referred to as ozone depletion potential. Chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs), two common refrigerants, have been recognised as significant ozone depletion culprits. Chlorine atoms, which are present in CFCs, are discharged into the stratosphere once they reach the high atmosphere. When these chlorine atoms are released, they can catalytically destroy ozone molecules, causing the ozone layer to weaken. HCFCs nevertheless have the ability to deplete the ozone layer, although being less dangerous than CFCs. They have the ability to degrade ozone molecules since they include chlorine and fluorine atoms.

To safeguard the ozone layer, the Montreal Protocol gradually phased out the manufacturing and use of CFCs and HCFCs. Also, traditional refrigerants, have high GWP values, including CFCs and HCFCs. In contrast to carbon dioxide (CO2) over a given time period, CFC-12, which is frequently used in older refrigeration systems, has a GWP of 10,900, suggesting that it significantly contributes to global warming. Despite having lower GWP values than CFCs, HCFCs nevertheless have an impact on global warming. A common refrigerant with a GWP of 1,810 is HCFC-22. These high GWP values highlight the need for alternative refrigerants with lower global warming potential.

Environmentally Friendly Refrigerants

- Natural Refrigerants: Natural refrigerants have drawn much interest as safe substitutes for conventional refrigerants. They stand out for their minimal potential for global warming, non-ozone-depleting qualities, and low or no environmental effect. Ammonia (NH3), hydrocarbons (HCs), and carbon dioxide (CO2) are three frequently utilised natural refrigerants.

- Hydrocarbons (HCs): Propane (R-290) and isobutane (R-600a), two Hydro-Carbons (HCs) that are naturally occurring substances, are low-GWP and ozone-depleting refrigerants. Small household refrigeration systems, vending machines, and commercial refrigeration equipment often employ HCs. They are very energy efficient and have good thermodynamic characteristics. Although hydrocarbons are extremely effective and have little influence on the environment, they are combustible and need for special safety precautions. To guarantee the secure use of hydrocarbon refrigerants, proper system design is required, including trustworthy leak detection and ignition prevention techniques.

- Hydrofluoroolefins or HFOs: A novel family of refrigerants called Hydrofluoroolefins (HFOs) has gained appeal as an alternative to conventional refrigerants that is less harmful to the environment. HFOs are made with strong thermodynamic characteristics, while having a low Global Warming Potential (GWP). The HFOs 1234yf and 1234ze are two HFOs that are often utilised.

The necessity to solve the environmental issues with conventional refrigerants, especially those with high GWP, led to the invention of HFOs. In an effort to lessen greenhouse gas emissions and slow down climate change, HFOs were created. GWP is significantly lower for these refrigerants than it was for their predecessors, such as hydrofluorocarbons (HFCs).

HFOs were created in an effort to balance performance and environmental effects. In accordance with worldwide legislation and activities focused on decreasing greenhouse gas emissions, HFOs minimise the impact of refrigeration and air conditioning systems to global warming by lowering the GWP.

- Hydrofluorocarbons (HFCs): Synthetic refrigerants called hydrofluorocarbons (HFCs) were created to replace ozone-depleting compounds like chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs). HFCs possess a substantial GWP and actively contribute to the phenomenon of climate change. even if they do not destroy the ozone layer. To lessen their environmental effect, attempts have been undertaken to find low-GWP substitutes and blends/mixtures.

Low-GWPHFC substitutes have been created in response to the demand for more ecologically acceptable refrigerants. These substitutes are designed to offer HFC-like thermodynamic features and performance with markedly less influence on global warming. HFC-32 (GWP of 675) and HFC-152a (GWP of 138) are two examples of low-GWP HFC substitutes. In comparison to conventional HFCs like HFC-134a (GWP of 1,430) and HFC-410A (GWP of 2,088), these substitutes offer a significant reduction in GWP while keeping effective cooling capabilities. These refrigerants are suitable for various applications such as chillers, heat pumps, air conditioners and refrigerators. A transitional road to more environmentally friendly refrigeration and air conditioning systems is made possible by the use of low-GWP HFC substitutes.

- Hydrofluoroethers (HFEs): These are synthetic refrigerants that have zero ODP and low to medium GWP. They are also non-flammable and have good thermal stability and compatibility with materials. Some examples of these refrigerants are R-E347mcc, R-E245fa2 and R-E245cb2. These refrigerants are mainly used as solvents, blowing agents and heat transfer fluids, but they can also be used as refrigerants for low temperature applications.

- Mixtures and Blends of Environmentally Friendly Refrigerants: In recent years, there have been several research conducted to explore the utilisation of mixtures and blends as a means to enhance the performance of environmentally friendly refrigerants. It was earlier studied about low-GWP refrigerants as environmentally friendly alternatives to R134a in low-temperature applications. The comparative analysis of operational efficiency of R1234ze/R134a, R1234yf/R134a, R1234ze/R32, and R1234yf/R32, aims to identify sustainable alternatives.

The 90:10 blend of R1234ze and R134a showed superior performance, making it a viable option for lower-temperature applications. The utilisation of natural refrigerants and their mixtures has been observed to be a successful strategy in mitigating the negative environmental impacts linked to chlorofluorocarbon (CFC) and hydrochlorofluorocarbon (HCFC) refrigerants. This adoption not only enhances the dependability and durability of refrigeration systems but also helps to protect the environment.

- Phase-Change Materials (PCMs): Phase-change materials (PCMs) are substances that, when heated to a specified temperature, may change their phase (solid-liquid or liquid-gas) and store and release thermal energy. The use of PCMs for thermal energy storage in a variety of sectors, such as air conditioning and refrigeration, has been investigated.

PCMs may be included in refrigeration and air conditioning systems to improve energy efficiency and lower peak load demand. PCMs can assist in controlling temperature variations and lowering the system’s total energy consumption by storing and releasing thermal energy throughout the phase change process.

The choice of suitable PCM for a refrigeration purpose relies on a number of variables, including the intended operating temperature range, heat transfer properties, and system compatibility. The goal of ongoing research is to create PCMs with enhanced thermal and durability characteristics to maximise their performance in refrigeration systems.

- Nano Refrigerants: A relatively recent and promising advancement in the refrigeration industry is the use of Nano refrigerants. They are made up of nano particles that are scattered throughout conventional refrigerants. The thermal characteristics of the refrigerant, such as thermal conductivity and heat transfer coefficients, can be improved by the nano particles, which are frequently metallic or oxide-based. The performance and energy efficiency of refrigeration systems can be increased by adding nano particles to refrigerants.

It is possible for nano refrigerants to increase heat transfer rates, lower refrigerant charges, and boost system dependability. Additionally, by enhancing system performance and lowering energy usage, they can help to reduce the overall impact on the environment. Although nano refrigerants have potential, further study is required to determine their long-term stability, safety issues, and environmental effect. The potential advantages of nano refrigerants must be carefully weighed against any potential hazards and difficulties in their actual application.

Challenges and Future Directions

Despite the advancements achieved in the creation of ecologically benign refrigerants, there are still many issues to be resolved. This section examines the future requirements for research and development as well as the technical difficulties and constraints, economic factors, and industry acceptance. The use of eco-friendly refrigerants might come with technological difficulties and restrictions. Certain refrigerants could differ thermodynamically from conventional ones, necessitating system modification and optimisation.

For a smooth transfer, it is essential to take into account compatibility with current equipment, including compressors, seals, and lubricants. Alternative refrigerants may differ from conventional ones in terms of performance qualities, including dependability, capacity, and efficiency.

Economic factors drive the use of ecologically friendly refrigerants, but the expense of alternative refrigerants, equipment upgrades, and system retrofits can make it difficult for the industry to adopt them widely.

To achieve economic viability, initial investment and long-term operational expenses must be thoroughly analysed. Refrigerants must be handled and stored correctly to prevent accidents and ensure system efficiency.

- Proper Training: Only qualified technicians should handle refrigerants. They have the necessary training to manage the chemicals safely.

- Appropriate Storage: Refrigerants should be stored in well-ventilated areas away from direct sunlight and heat sources. Cylinders should be kept upright and secured to prevent tipping.

- Personal Protective Equipment (PPE): Technicians should wear appropriate PPE, including gloves and safety goggles when handling refrigerants to protect against exposure.

Government incentives, legislation, and industry efforts may play a significant role in fostering the use of ecologically friendly refrigerants.

Conclusions

The use of environmentally friendly refrigerants is crucial for sustainable and energy efficient refrigeration and air conditioning systems. Based on studies, it is found that no refrigerant meets all technological and environmental criteria for sustainable refrigeration and air conditioning. Therefore, the selection of the best refrigerant depends on the specific application, system design, safety requirements, cost-effectiveness, and availability.

Dr. (Prof.) D. B. Jani received Ph.D. in Thermal Science (Mechanical Engineering) from Indian Institute of Technology (IIT) Roorkee. Currently he is a recognized Ph.D. Supervisor at Gujarat Technological University (GTU). He has published more than 250 Research Articles in reputed International Conferences and Journals. He has also published 10 reputed books and book chapters in the area of thermal engineering. He is an Academic Editor for the Journal of Materials Science Research and Reviews. Presently, he is an Associate Professor at GEC, Bhavnagar, Gujarat Technological University, GTU, Ahmedabad (Education Department, State of Gujarat, India). His area of research is Desiccant Cooling, ANN, TRNSYS, and Exergy.